Application Scope

- Suitable for hazardous areas such as chemical industry, oil refining, oil exploitation, offshore oil platforms, oil tankers and military industry.

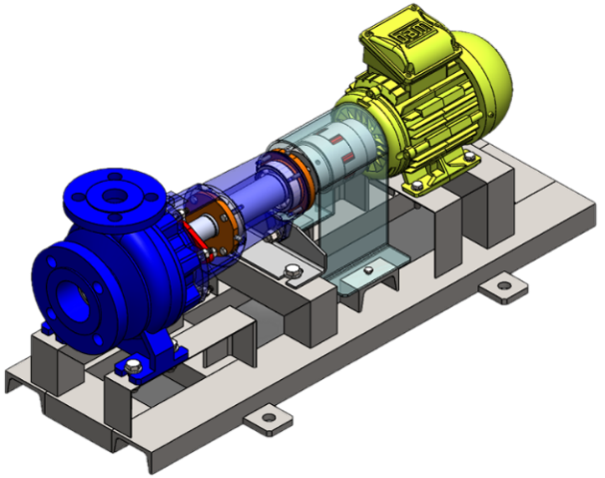

- Suitable for on - site control panels of offshore platform water injection pumps, export pumps, compressors, electric drag pumps, dual media, etc.

| Voltage: | AC220V / AC380V |

| I/O Points: | 256 (Expandable) |

| Communication: | RS485/Ethernet, etc.; |

| Explosion - proof Grade: | Ex db ⅡB T6 Gb + Ex db ec ⅡB T4 Gc |

| Size: | ≤ ≤ 1000*1500*450mm |

| Features: | Can be used in hazardous areas of Zone 2 and Zone 22; touch screen can be operated externally. |

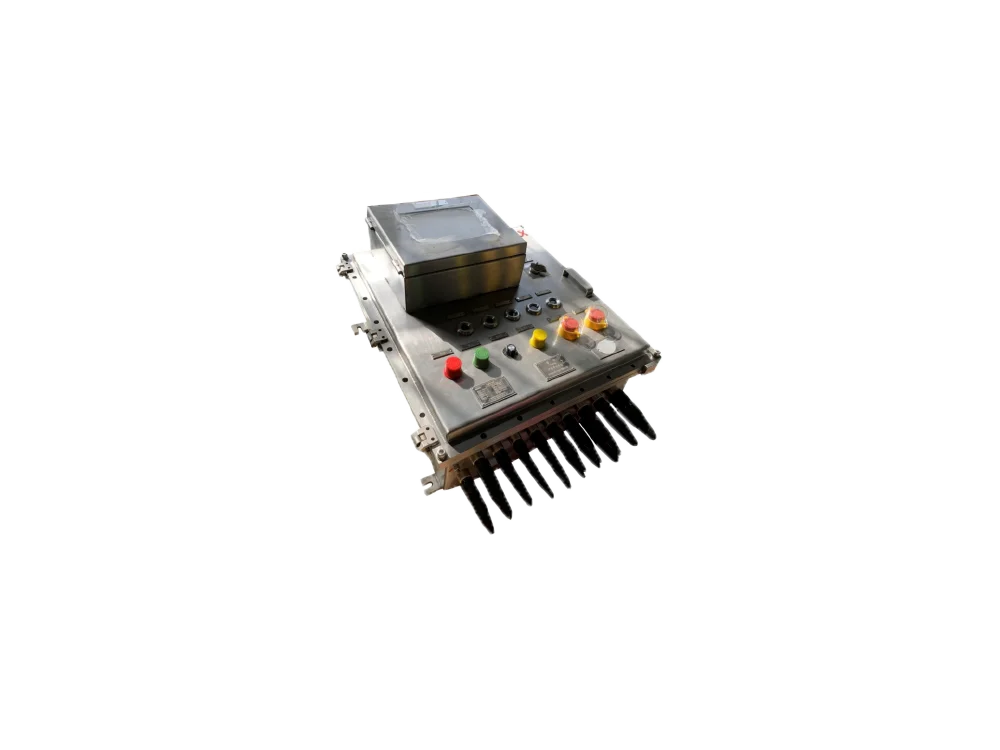

1. System Display - Pump Type

Composition: S7 - 200 smart + touch screen TP700 + single - chamber explosion - proof distribution box.

Temperature Collection

Monitoring of motor, pump, and winding temperature parameters; decoupling of alarm and shutdown parameters.

Frequency Conversion Monitoring

Voltage regulation and frequency modulation, V/F frequency modulation, motor self - learning, multi - speed, multi - function customization; motor operation status, voltage, current, speed and other

Vibration Collection

Voltage regulation and frequency modulation, V/F frequency modulation, motor self - learning, multi - speed, multi - function customization; motor operation status, voltage, current, speed and other parameters.

Communication

Diversified communication, compatible with communication collection of various on - site equipment for upper computer reading.

2. Compressor

Composition: S7 - 1200 + touch screen TP1200 + positive pressure ventilated cabinet.

Nature Gas Compressor

Using Chinese, human-machine interface touch screen as control panel , which can monitor various instruments and operation signals of the compressor. When the set value is exceeded, an alarm signal can be sent. It can also be started and stopped remotely. When the compressor fails, a fault signal can be sent to the PCS.

3. Filtration

Composition: S7 - 1500 + touch screen TP1500 + single - chamber openable explosion - proof distribution box.

Manual Backwashing:

Visual operation on the panel, one - key start/stop, easy to operate.

Automatic Backwashing:

External backwashing signal input or feedback through on - site pressure difference and time interval.

Conditional Start:

The pressure difference filtration interval is set to 60 minutes. The equipment is started through the pressure difference condition. If the interval between two times is less than 60 minutes, an alarm will be triggered.

Self - inspection Mode:

After the system receives the valve open - in - place signal, the valve will automatically close; when the system receives the valve close - in - place signal, the self - inspection is completed.

Feedback Monitoring:

If the valve fails to reach the open or close position within 15S, a valve feedback fault will be triggered.