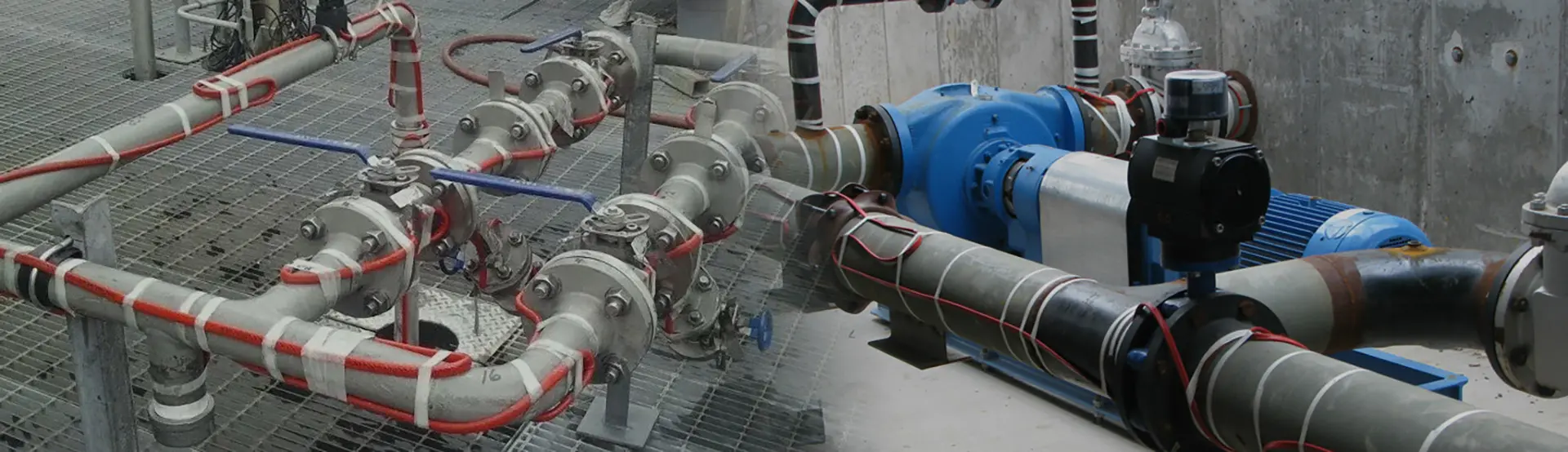

电机完整性

电机完整性智能监控系统将智能润滑监测终端与绝缘监控系统集成在一起,实现电机全生命周期自我维护。这降低了劳动力成本,同时确保了安全和无故障的生产作。

01

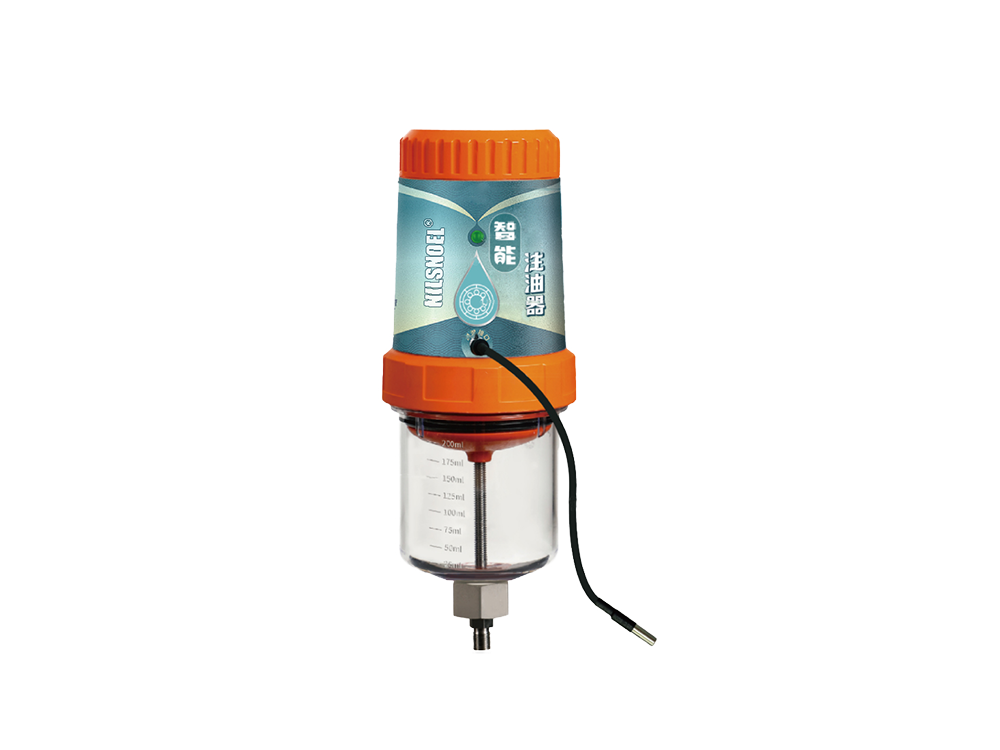

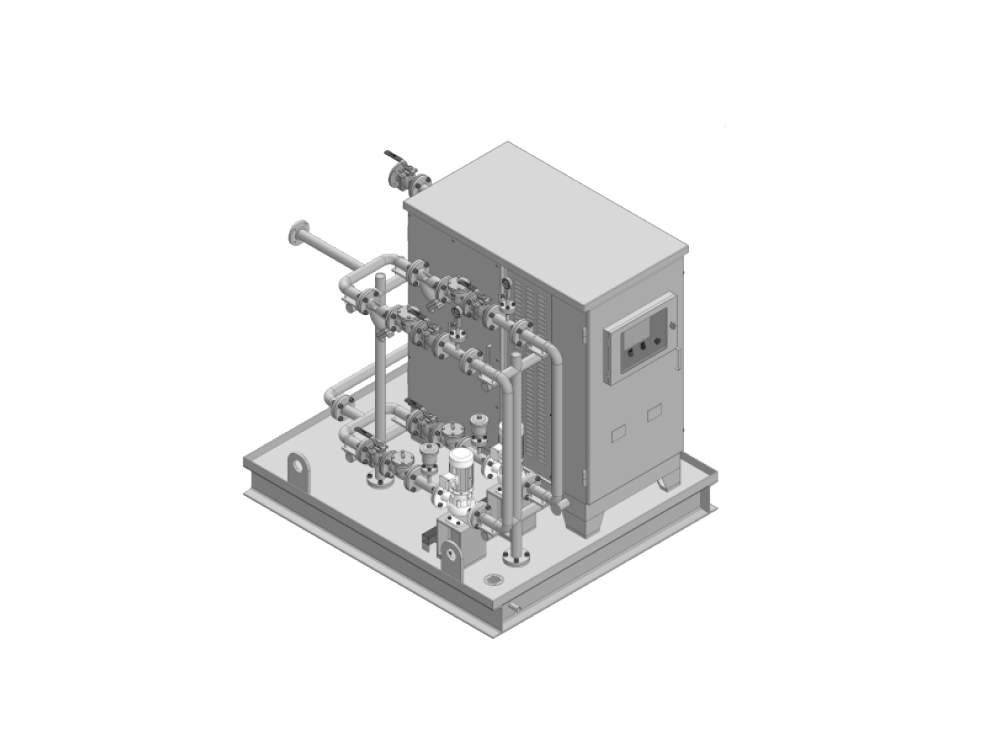

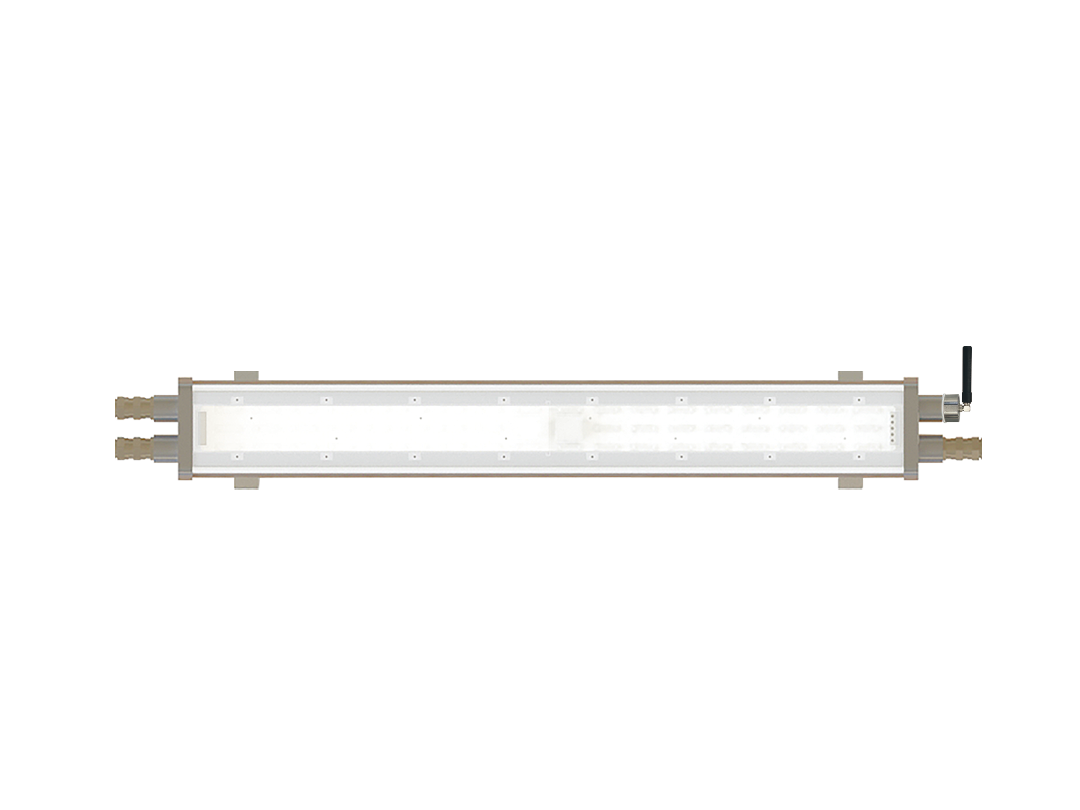

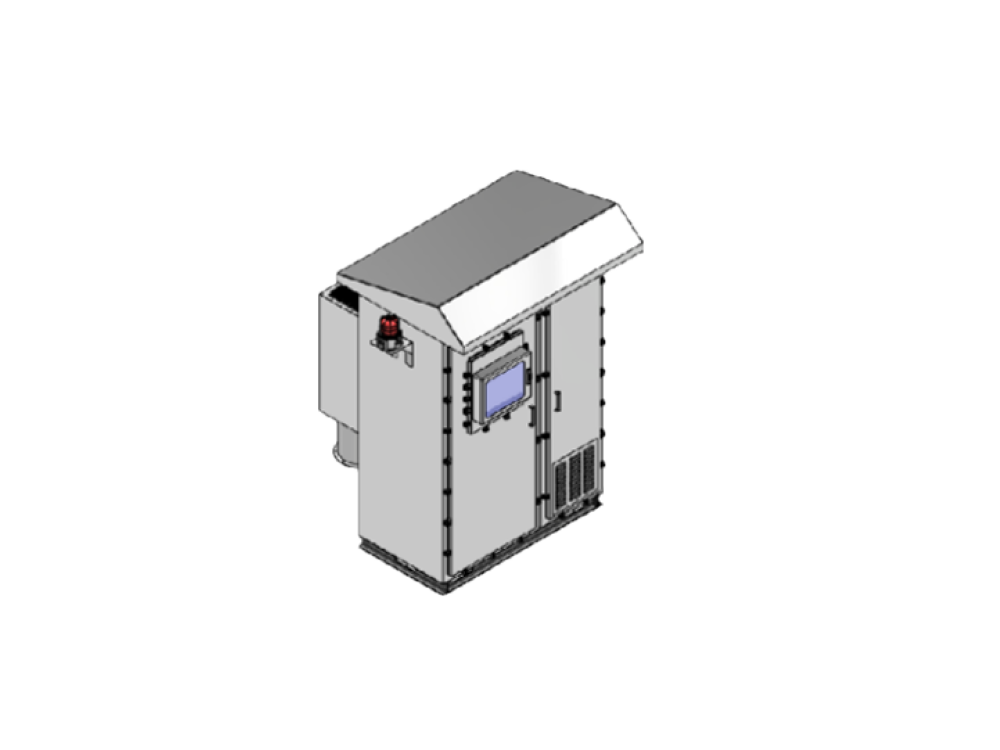

智能润滑监测终端

智能终端是集发电、润滑、监控功能于一体的全无人值守设备监控润滑系统。支持设备全生命周期自我维护,降低运营成本,保证安全可靠的生产。

核心技术

————————

自给自足的动力和智能能源供应

配备双存储(超级电容+锂电池),系统支持长达72小时的离线运行。在停机期间,它会自动切换到备份存储,确保关键数据安全并持续监控静态设备状态。

轴电流抑制和保护

获得专利的导电环与光纤结构相结合,建立了低电阻接地路径,将轴电流降低到 <5 mA。这将轴承使用寿命延长多达 3 倍,并将电机故障减少 30%。

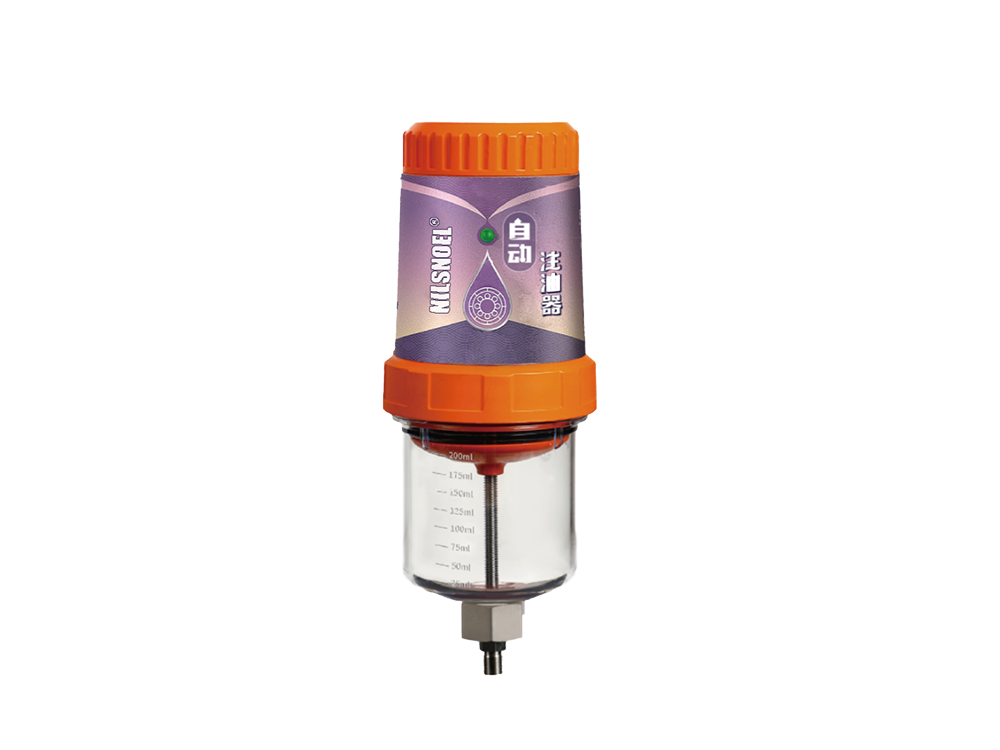

自适应智能润滑系统

提供精确的智能注油,动态补充基础油,重建润滑脂成分。这实现了持久的轴承润滑并再生了降解的润滑脂。

多模态条件监控系统

将温度、振动和声学监测集成在多模态诊断框架中。借助人工智能驱动的算法,它可以准确识别轴承磨损、不对中和其他故障,实现超过 95% 的预测准确率。系统支持实时分析、远程告警、现场可视化等。

智能自润滑系统

具有在线润滑脂修复、再生和“自愈”功能。使电机无需重新润滑即可运行长达三年,从而提高运行可靠性并降低维护成本。

实时状态监测

提供轴承温度和振动在线监测,具有无线实时数据传输和报警功能。

集成系统互联

与电气监控系统和 IT 网络兼容。支持将非电气钥匙电机信息上传到DCS,满足智慧企业数字化需求。

智能诊断预警

配备数据采集、分析、学习和状态评估功能。为基于状态的电机维护提供可作的见解。

移动管理平台

专用设备健康APP提供仪表盘、产线分布、设备概览、报警处理、缺陷提交、维护记录提交等功能。

02

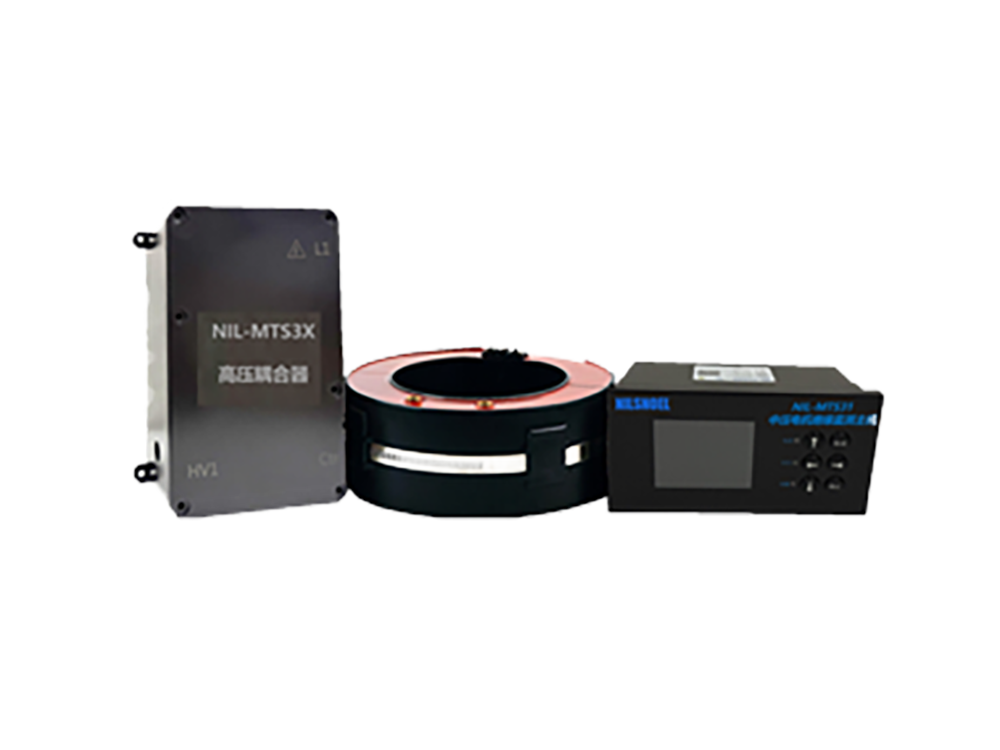

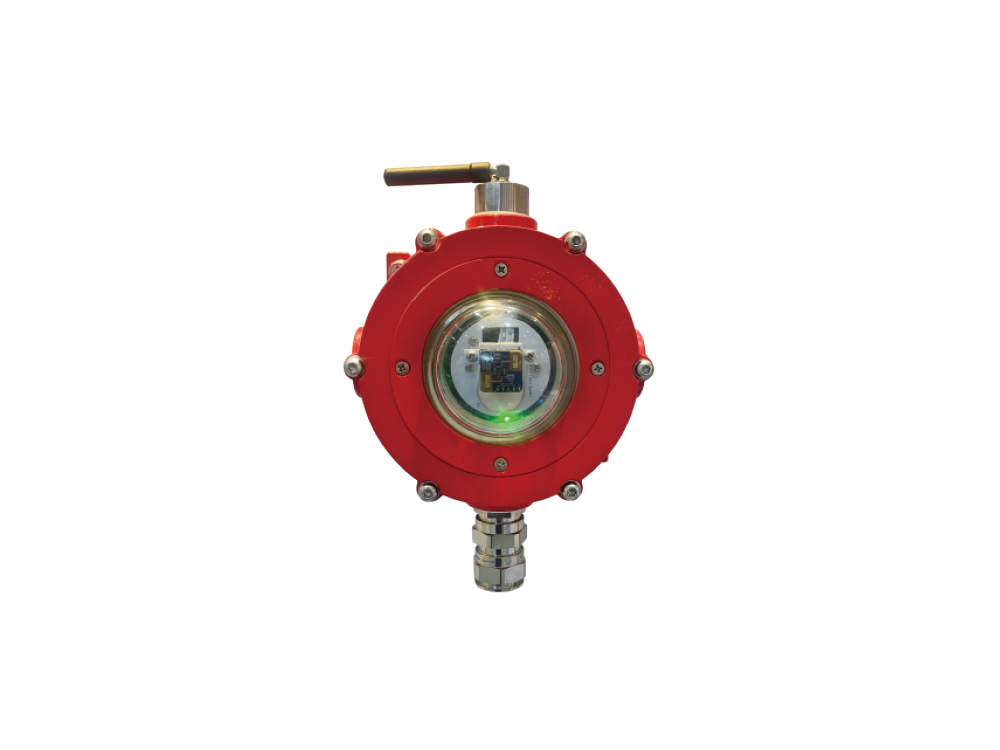

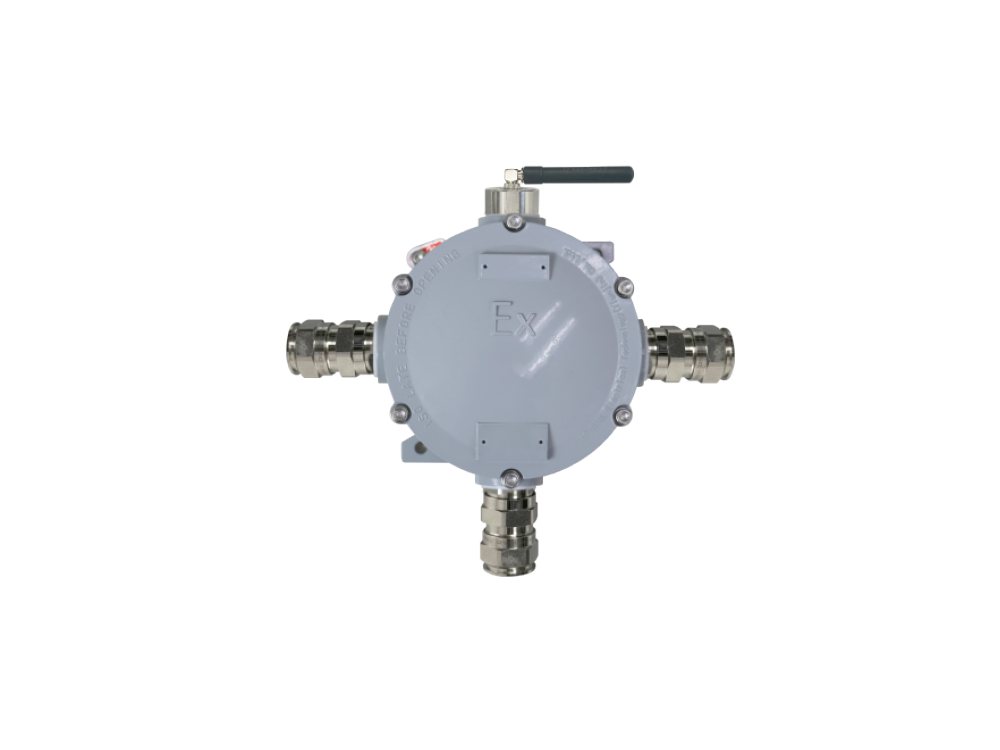

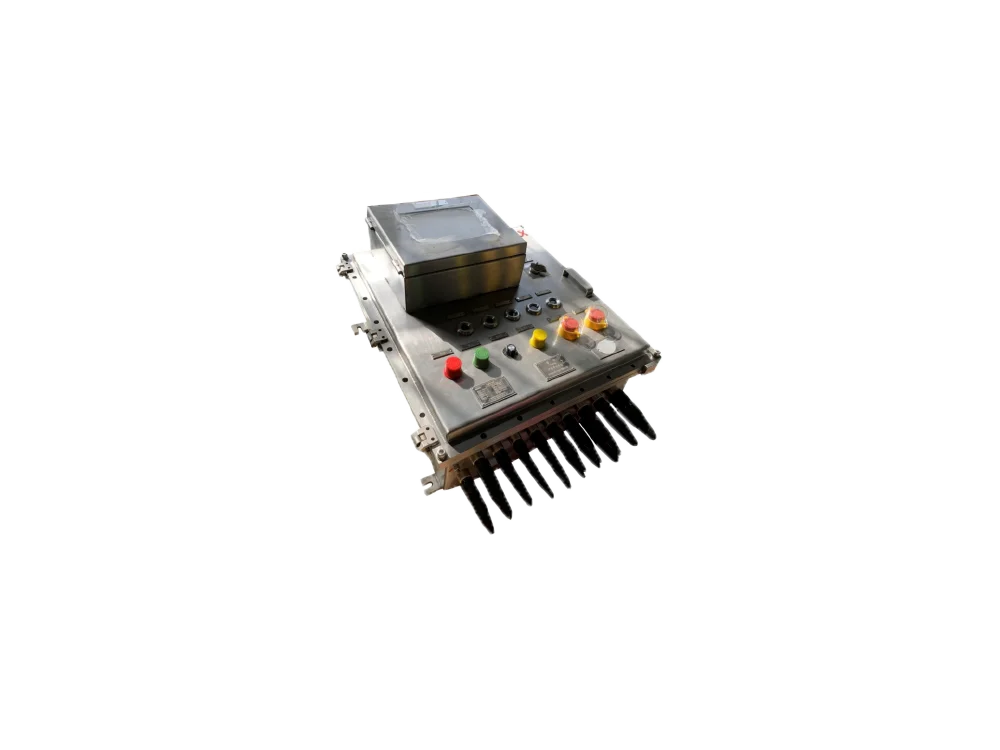

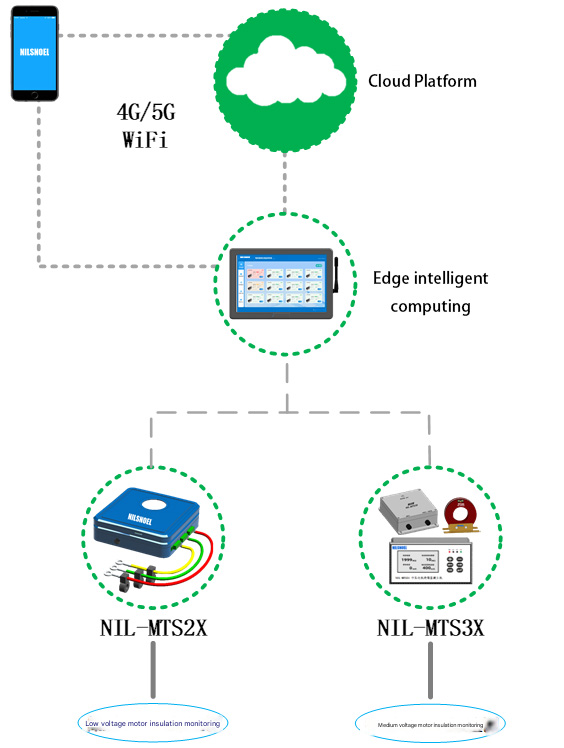

绝缘监测系统

在电机运行期间,绝缘传感器连续测量电机电源参数。当电机停止时,系统采用直流注入法来测量绝缘性能。通过多维参数分析,对电机绝缘特性进行全面的测量、分析和诊断。适用于三相感应电动机、同步电动机、鼠笼式电动机、绕线转子电动机。

优势和特点

————————

全场景智能监控

在线剩余电流监测和离线绝缘电阻测量自动切换,覆盖电机运行和关机场景。

跨平台智能连接

支持云平台、手机APP、小程序、PC端,实现智能监控,便捷管理。

高精度数据采集

绝缘电阻精度<3%,零序电流精度<2%,确保数据可靠准确。

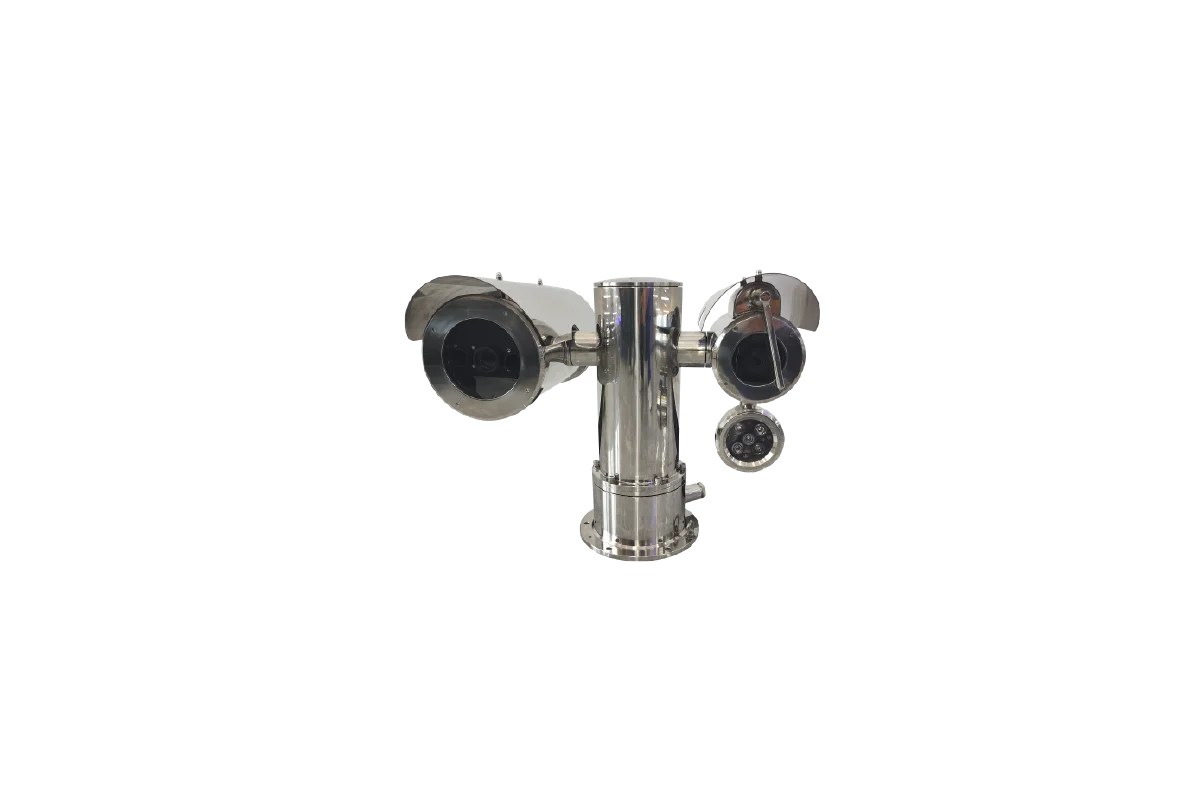

恶劣环境中的可靠性

通过Ex ia IIC T4 Ga防爆等级和电磁兼容测试,适用于石化厂等危险环境。

在线客服

在线客服