-

-

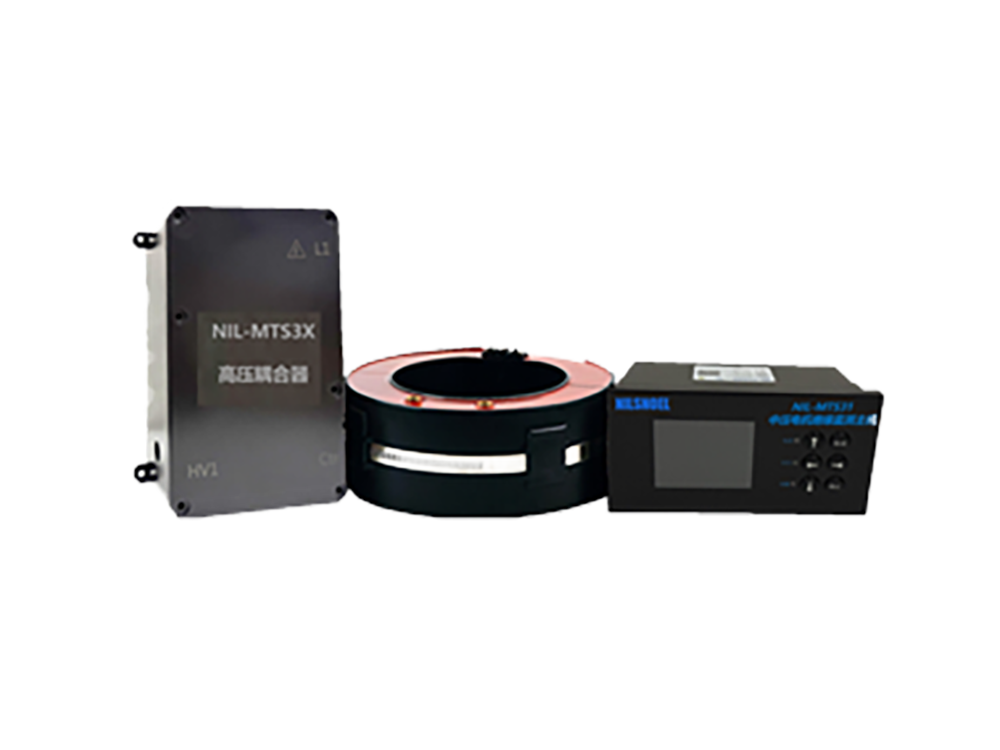

变压器多维监控变压器运行情况的实时采集,发现解决变压器内部瞬态突发故障和缓慢发展的潜在故障

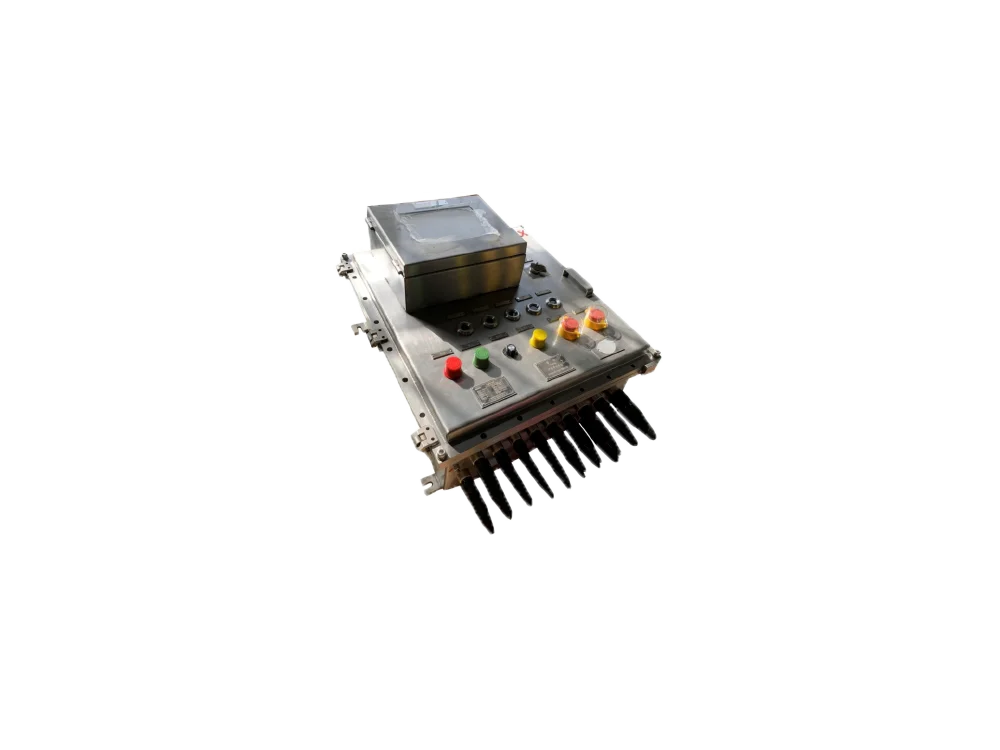

变压器多维监控变压器运行情况的实时采集,发现解决变压器内部瞬态突发故障和缓慢发展的潜在故障 中压盘一键顺控和智能监测方案根据自动化系统命令,自动执行隔离开关动作。改变变电站电气设备在各种模式之间自动转换

中压盘一键顺控和智能监测方案根据自动化系统命令,自动执行隔离开关动作。改变变电站电气设备在各种模式之间自动转换 电机完整性将智能润滑监测终端与绝缘监控系统集成在一起,实现电机全生命周期自我维护

电机完整性将智能润滑监测终端与绝缘监控系统集成在一起,实现电机全生命周期自我维护 吊机一体化解决方案该系统提供实时、准确、有效的起重机运行状况反映,并具有设备性能的连续监控、数据记录和历史回放的功能

吊机一体化解决方案该系统提供实时、准确、有效的起重机运行状况反映,并具有设备性能的连续监控、数据记录和历史回放的功能 -

雾笛导航系统在能见度较低的情况下自动激活导航设备(雾喇叭/灯),向附近的

雾笛导航系统在能见度较低的情况下自动激活导航设备(雾喇叭/灯),向附近的

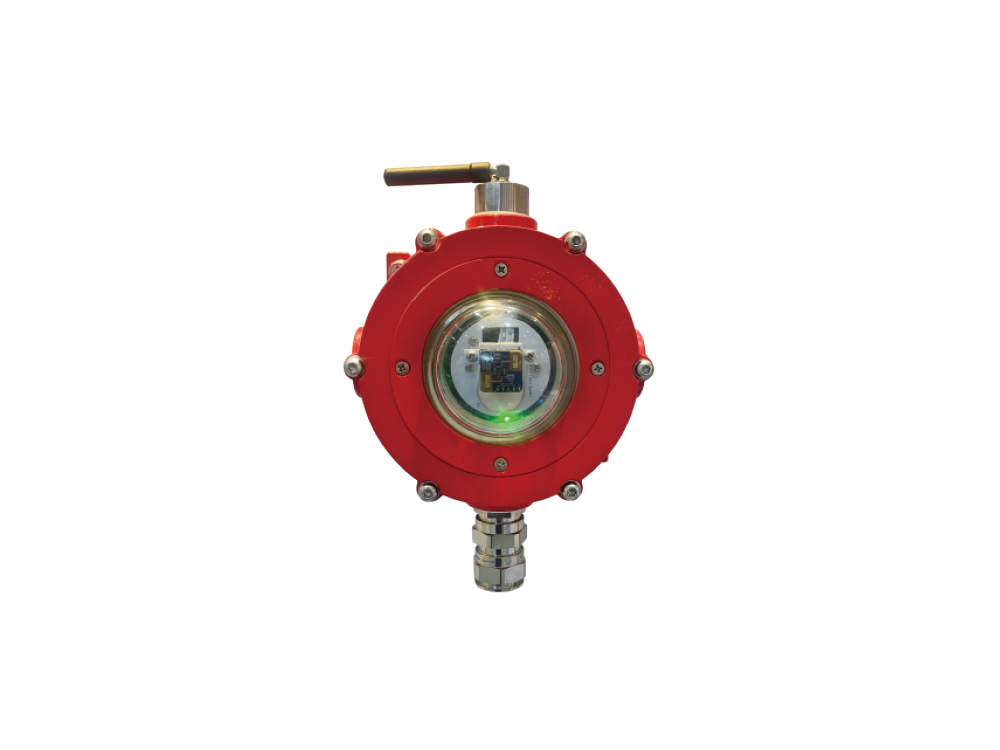

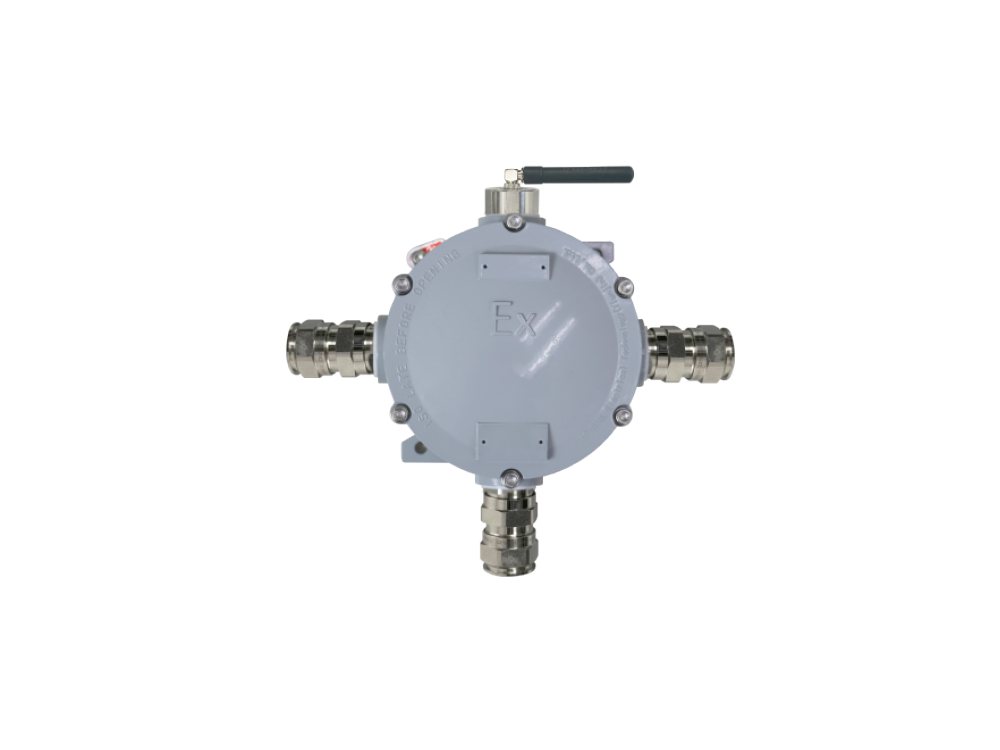

船只/飞机标记位置警报。 激光式气体监测系统自动化、非接触式、可视化,可在预设区域进行24/7全天候气体泄漏检测。

激光式气体监测系统自动化、非接触式、可视化,可在预设区域进行24/7全天候气体泄漏检测。 极早期火灾预警系统通过检测空气中的粉尘/基础颗粒,以在最初有产生火苗的趋势时就发出报警,防患于未然

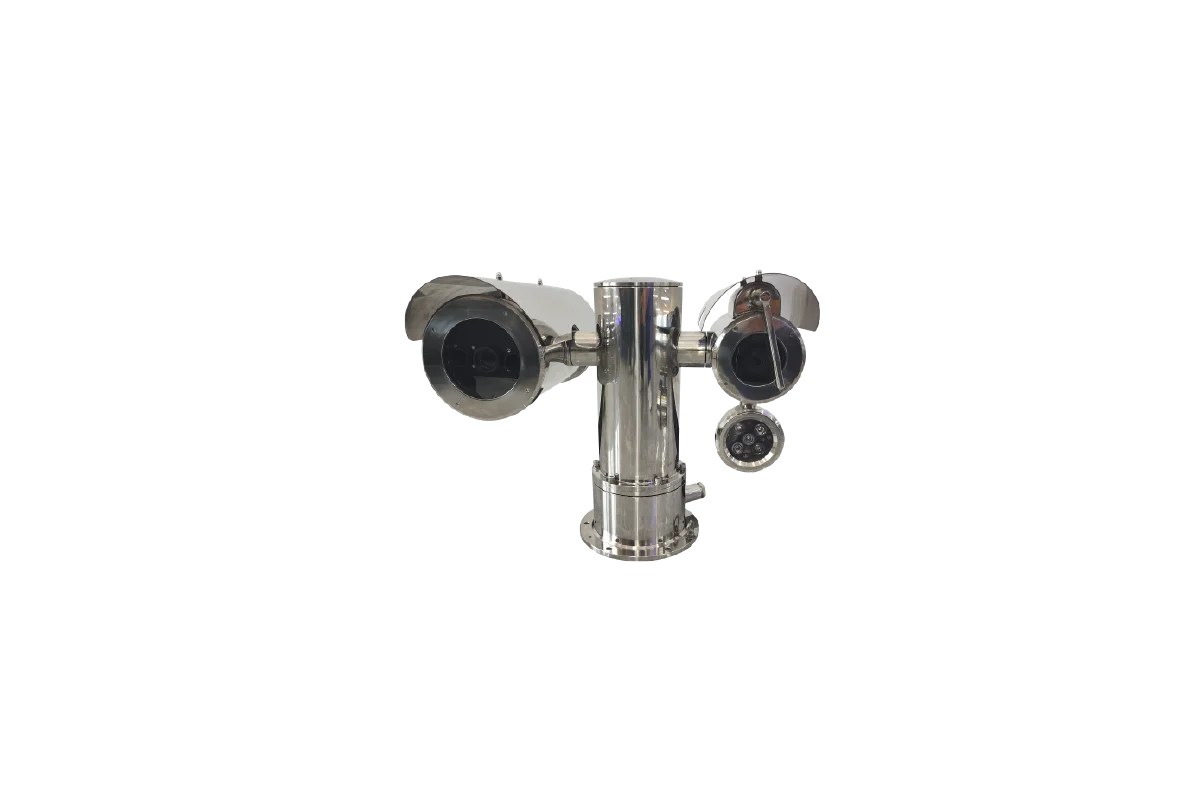

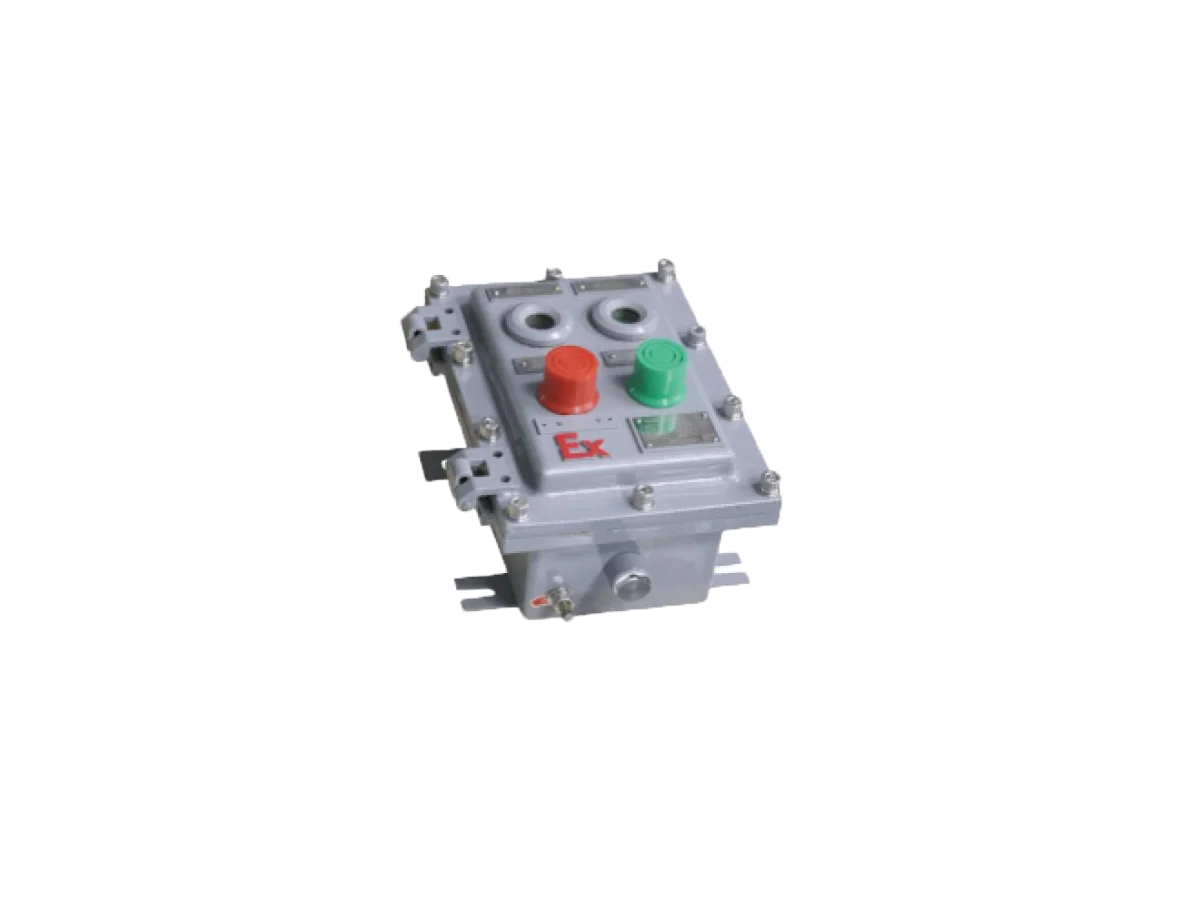

极早期火灾预警系统通过检测空气中的粉尘/基础颗粒,以在最初有产生火苗的趋势时就发出报警,防患于未然 防爆溢油监测系统通过非接触检测的方式,全天候、实时地监测重点水域的油污情况

防爆溢油监测系统通过非接触检测的方式,全天候、实时地监测重点水域的油污情况 海上平台周界安全管理系统监控未经授权的船舶靠近平台,对于非法登临平台的人员采用强声予以警告驱离

海上平台周界安全管理系统监控未经授权的船舶靠近平台,对于非法登临平台的人员采用强声予以警告驱离 -

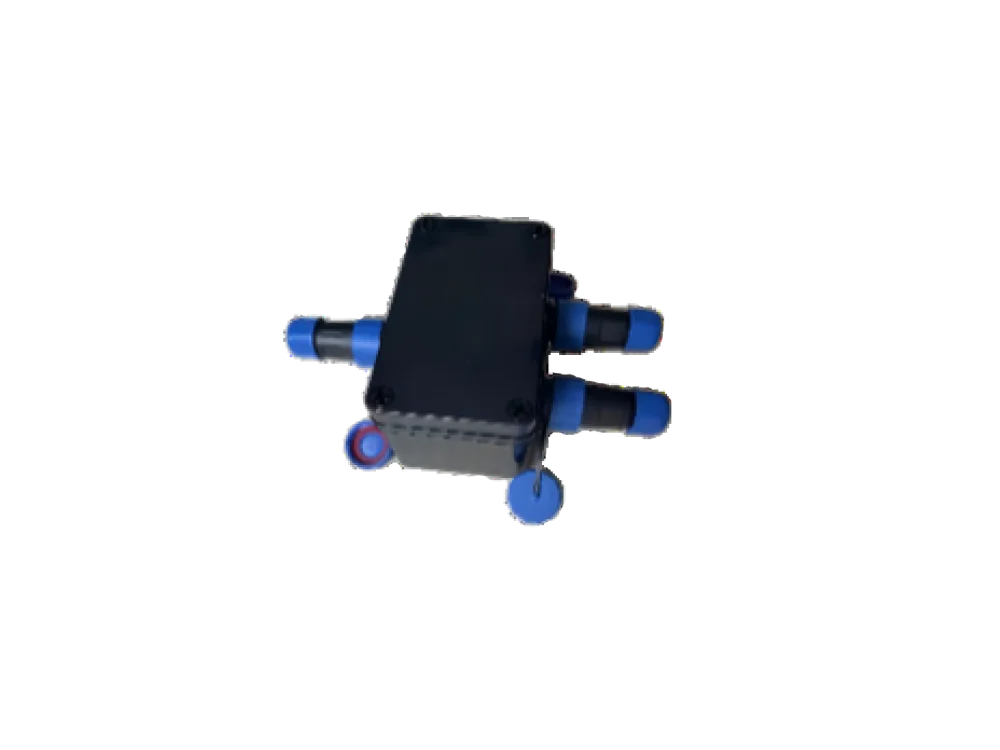

智慧控制电伴热利用无线通信实时传输数据,将供暖需求与功率输出动态匹配,构建多元协同协同的智能热管理网络

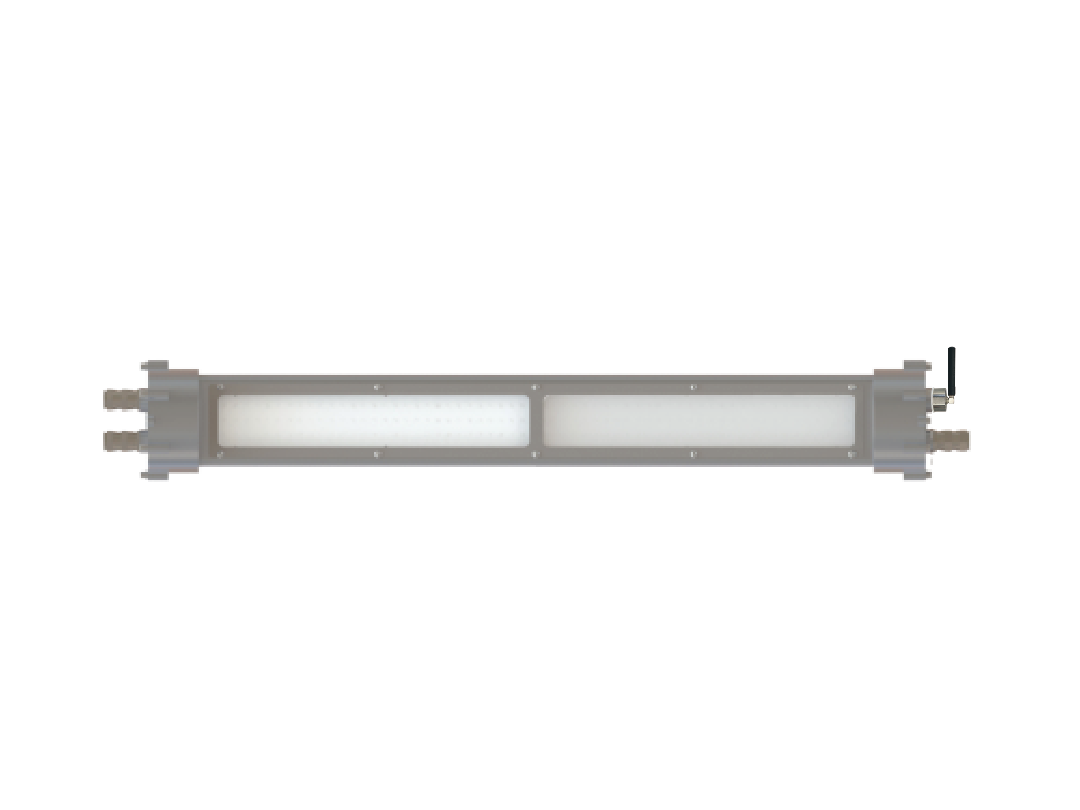

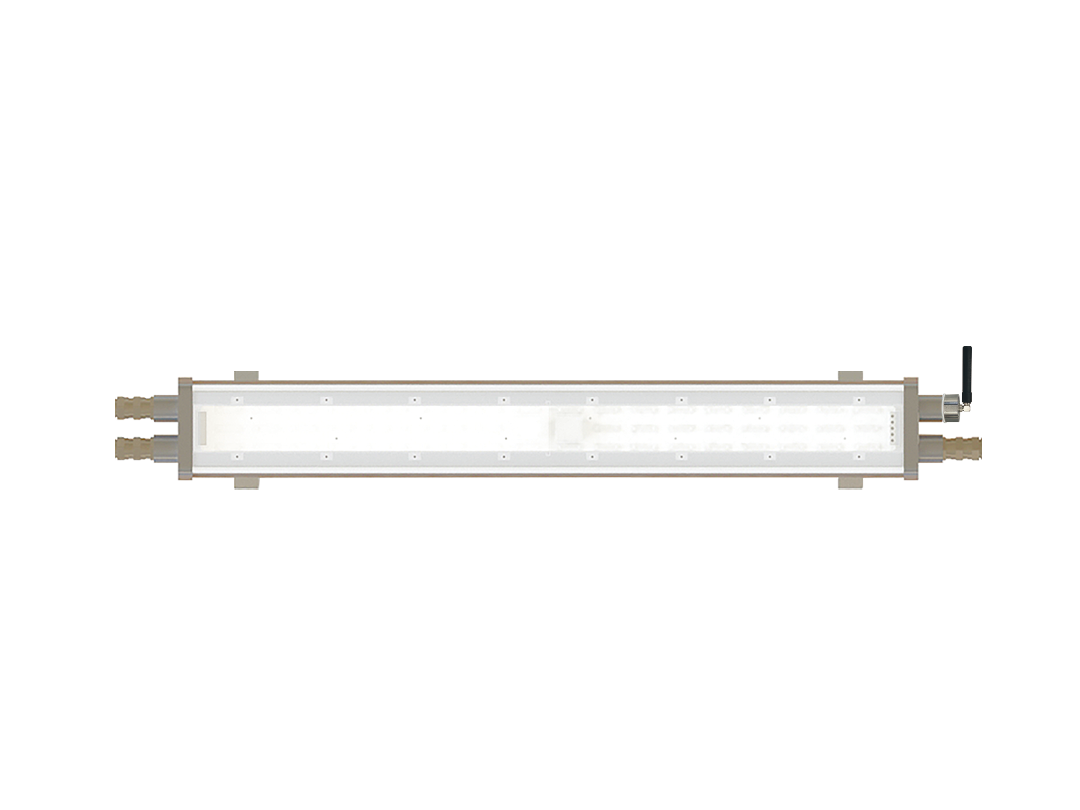

智慧控制电伴热利用无线通信实时传输数据,将供暖需求与功率输出动态匹配,构建多元协同协同的智能热管理网络 智慧照明控制系统根据不同的工作环境和要求,集成不同的传感器和智能设备,实现照明设备之间的高效通信和精确智能控制

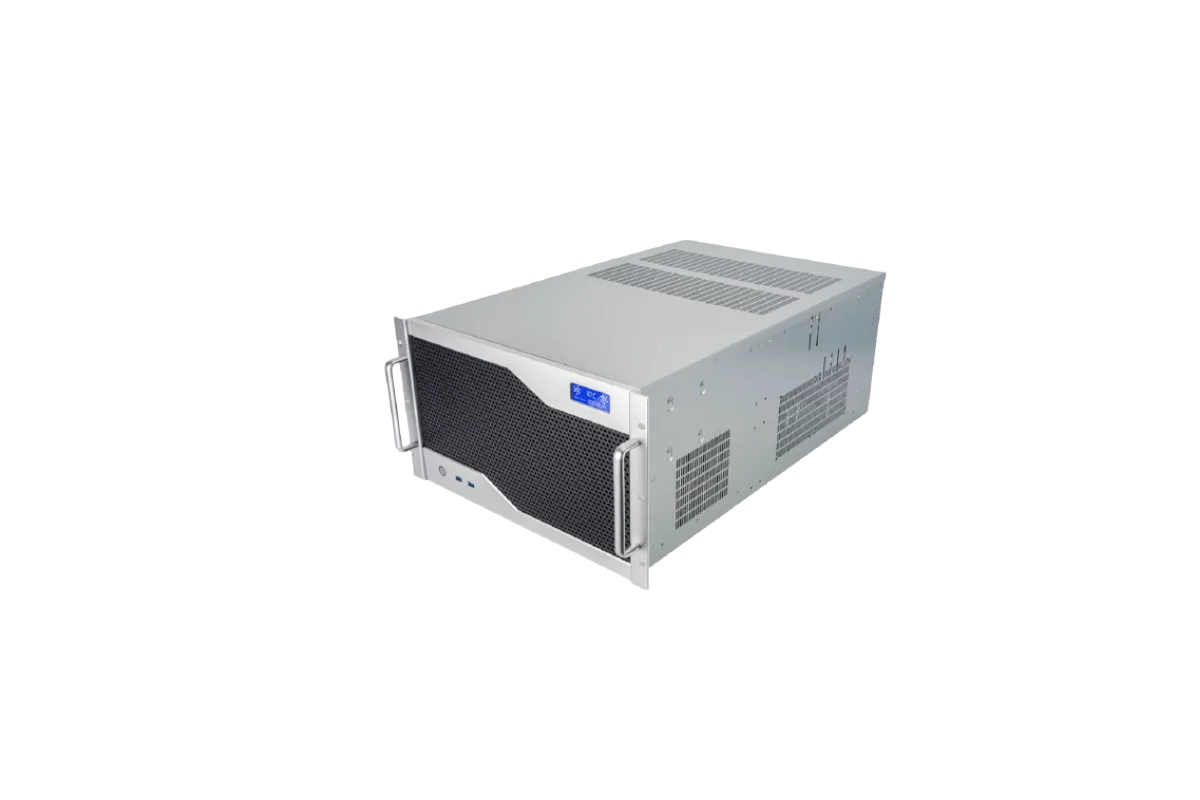

智慧照明控制系统根据不同的工作环境和要求,集成不同的传感器和智能设备,实现照明设备之间的高效通信和精确智能控制 电磁加热节能系统电磁加热节能设备集成了PLC控制系统和远程监控功能,帮助企业构建高效、智能的节能管理系统

电磁加热节能系统电磁加热节能设备集成了PLC控制系统和远程监控功能,帮助企业构建高效、智能的节能管理系统 风机换热系统优化室内通风和换热风机。在保证室内通风和热交换的基础上,进一步优化风量,提高能效

风机换热系统优化室内通风和换热风机。在保证室内通风和热交换的基础上,进一步优化风量,提高能效 智磁节能系统定制化的电磁参数设计,可以有效降低谐波,抑制瞬态冲击,从而从系统层面实现节能降耗和设备保护

智磁节能系统定制化的电磁参数设计,可以有效降低谐波,抑制瞬态冲击,从而从系统层面实现节能降耗和设备保护 相控调压系统精确控制晶流管的导通角度,实现输出电压的平滑调节,从而达到节能目标

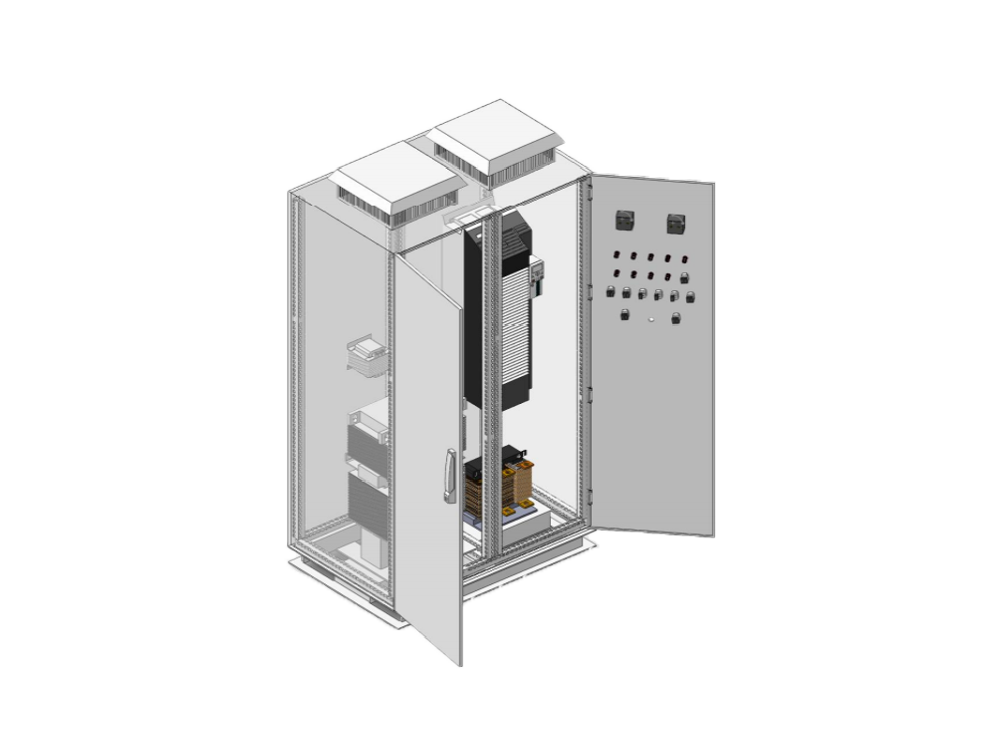

相控调压系统精确控制晶流管的导通角度,实现输出电压的平滑调节,从而达到节能目标 变频控制柜解决方案调节电机电源的频率和电压,从而实现交流电机的平稳启动、精确的速度控制和智能保护

变频控制柜解决方案调节电机电源的频率和电压,从而实现交流电机的平稳启动、精确的速度控制和智能保护

-

-

-

新闻公司及品牌最新信息项目案例项目案例分享

-

售后申请技术支持和售后通道下载中心产品资料、软件和系统

-

可持续性环境、社会责任和公司治理线上展厅详细了解尼尔森业务和产品联系我们随时联系,覆盖全球关于我们快速了解尼尔森诺尔

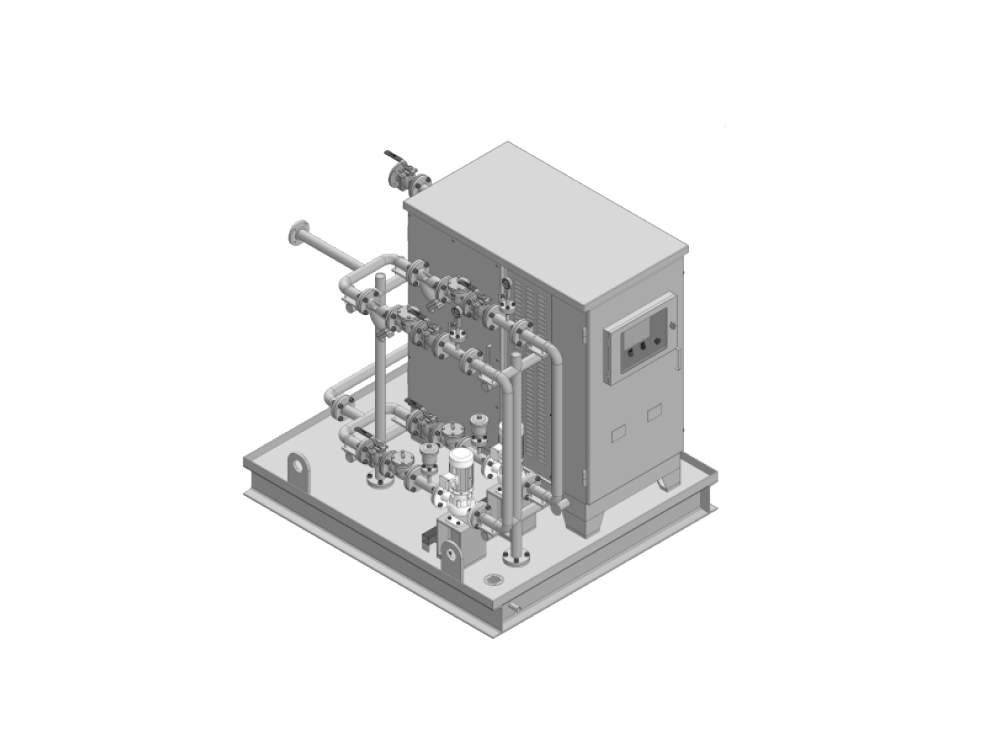

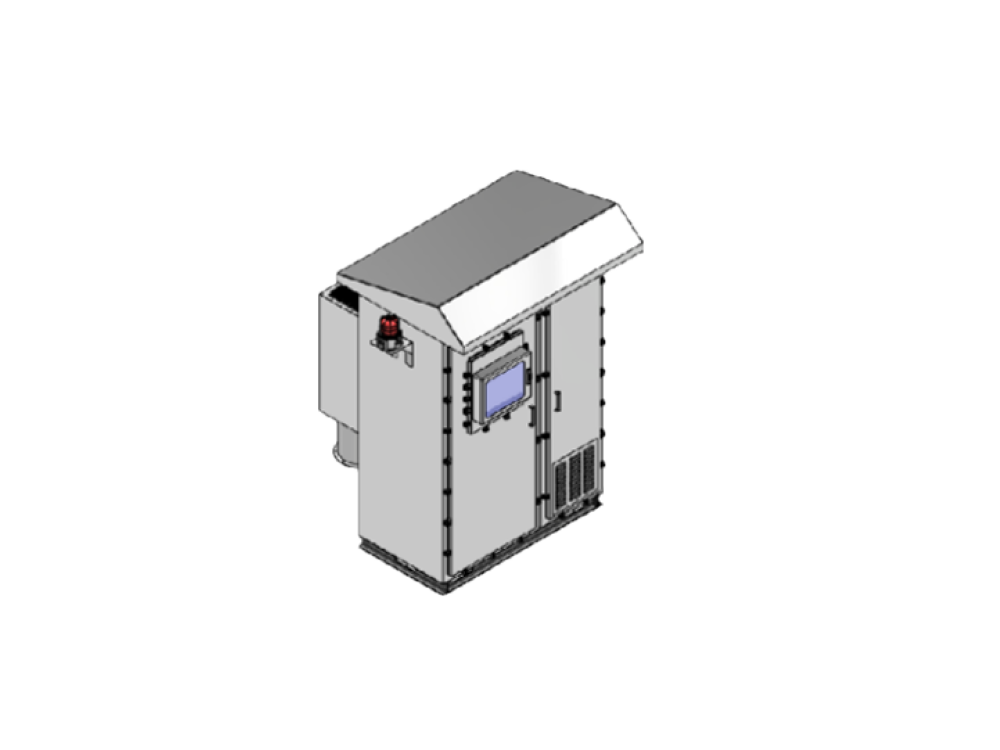

电磁加热节能系统

当前,许多海上石油平台的生产加热器仍采用传统的电加热管加热方式。这种方式虽然简单易行,但存在加热慢达不到做需温度、能耗高、热效率低、故障率高导致维护成本大等问题。特别是在海上环境中,电力供应相对紧张,电加热管加热方式不仅增加了平台的运营成本,还可能对电网稳定性造成一定影响。

我司将电加热改为变频电磁加热,电磁加热技术相比其他的加热手段,在加热效率,加热温度,使用寿命和体积上更有优势,高频电磁加热装置解决石油石化行业的管道加热问题、解决原油开采时由于温度低造成管道压力增高、产量无法提升困难,电磁加热改变传统并口加热问题。

Powerful Foghorn

————————

技术原理

——————

变频电磁供热系统的核心是采用电磁感应原理, 将电能转化成热能,在控制器内由整流电路将50Hz 的交流电压变成直流电压, 再经过控制电路将直流 电压转换成频率为10-22kHz的高频交流电压。 高频 交流电压流过缠绕在非金属材料管外的高频导线, 高速变化的磁场内部产生的磁力线切割非金属材料 管内部的金属容器时产生无数小涡流,使介质(如水, 原油,可燃气等)迅速加热,达到快速加热介质的效果。

首先,通过给线圈通电来产生磁场。当线圈通电时,电流在线圈中形成圆形磁场,这是由电子在导线中自由运动产生的。

当加热物体处于线圈的磁场中时, 磁 场会对物体内部的电子产生作用力。 根据洛伦兹力定律, 电子在磁场中会 受到一个垂直于电子速度和磁场方向 的力,使电子产生一个环形运动,便会 引起相邻电子之间的碰撞, 导致电子 的能量转化为热能。

在物体内部产生的涡流也被称为 涡电流。 它主要从物体表面向内 部传输热量。物体内部的温度升高, 表面的温度也会随之升高。当线圈 通电的电流增大时,磁场的强度也 会增大,进而使涡电流的强度增大, 从而导致物体加热更快。

洛伦兹力定律

涡流加热

磁场产生

应用图示

————————

在线客服

在线客服