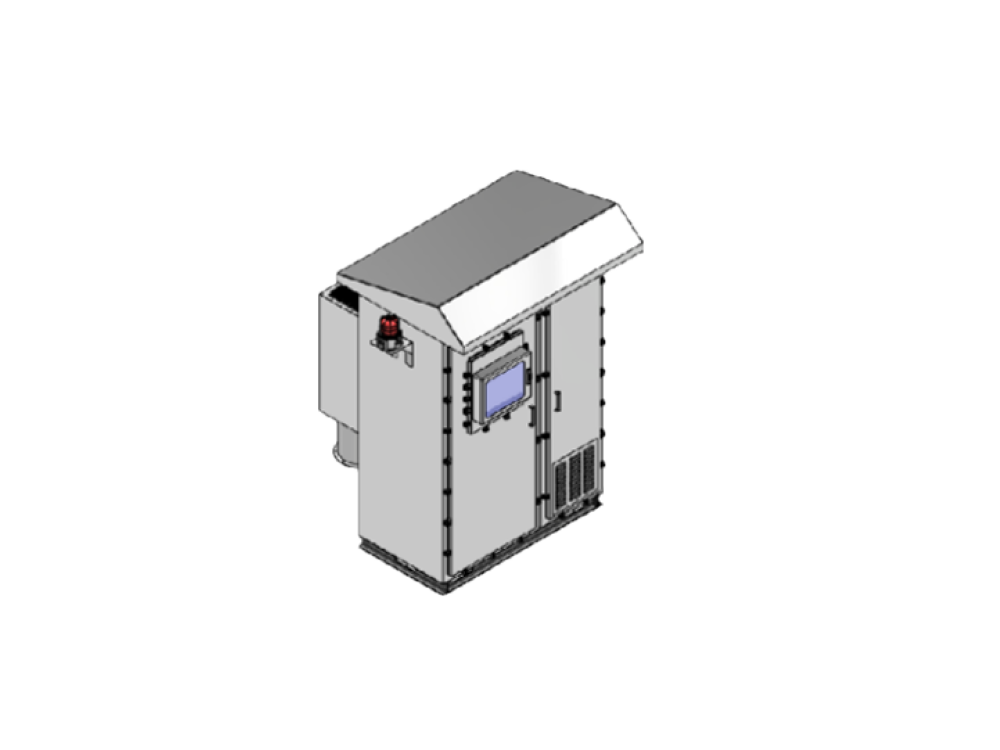

中压盘一键顺控和智能诊断解决方案

中压盘一键顺控和智能诊断解决方案

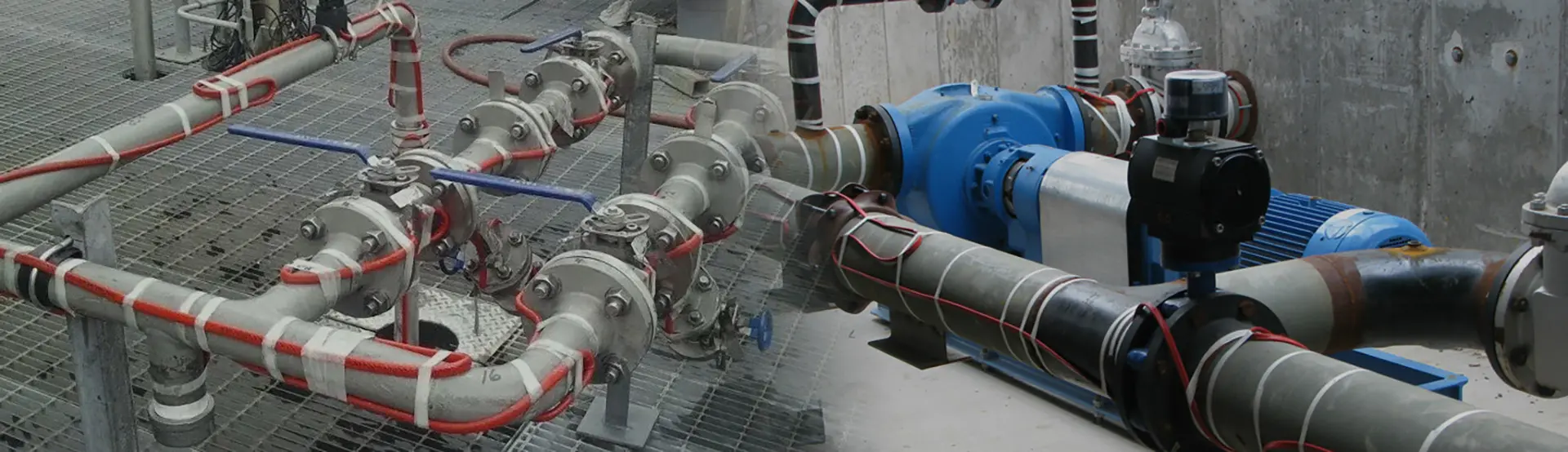

中压盘一键顺控及智能诊断方案 ,根据自动化系统命令,按照预先定义的运行逻辑和五防联锁规则,自动执行一系列隔离开关作。此过程改变了系统的运行状态,并使变电站电气设备能够在运行、热备用和冷备用模式之间自动转换,而无需人工干预。

系统集成多源异构传感器数据,实现设备与环境实时监测、状态可视化、阈值预警、历史数据分析,全面赋能设备智能运维。

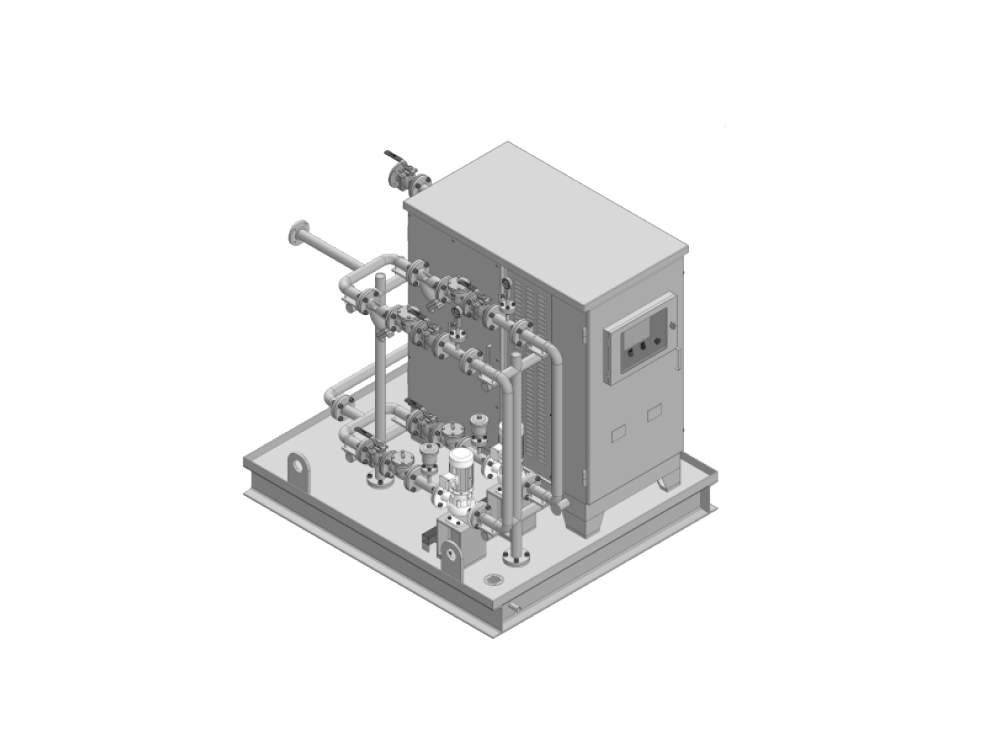

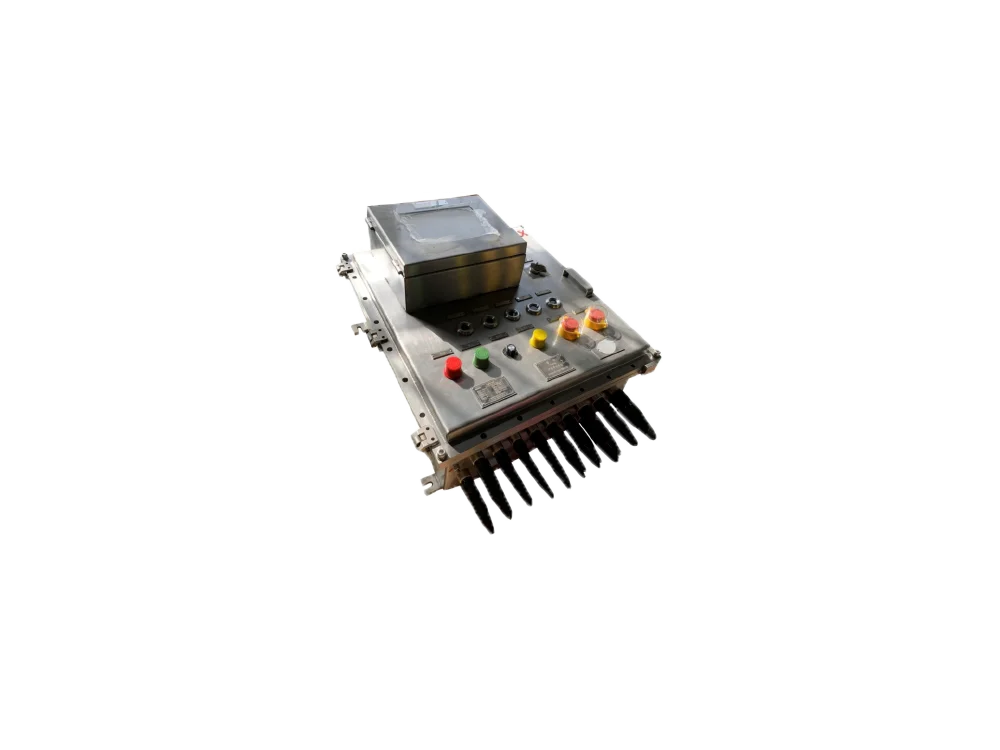

电动底盘车及地刀控制

可实现对电动机构的控制和保护, 控制器 可在电动机构驱动电机运行受阻达到保护条件 时立即对电机制动。 电动底盘车在控制器的控 制下可以实现断路器的手动或电动的摇入 / 摇 出控制,当发生堵转时,会智能判别故障电流状 态,将断路器退回到安全位置。

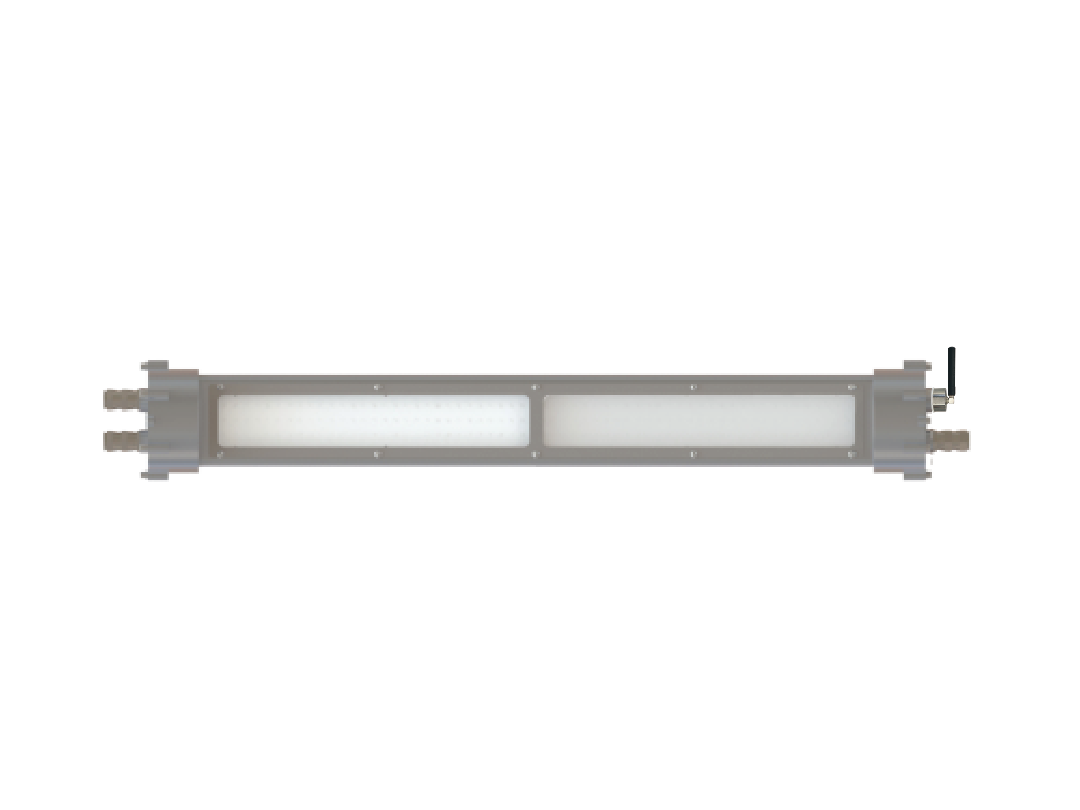

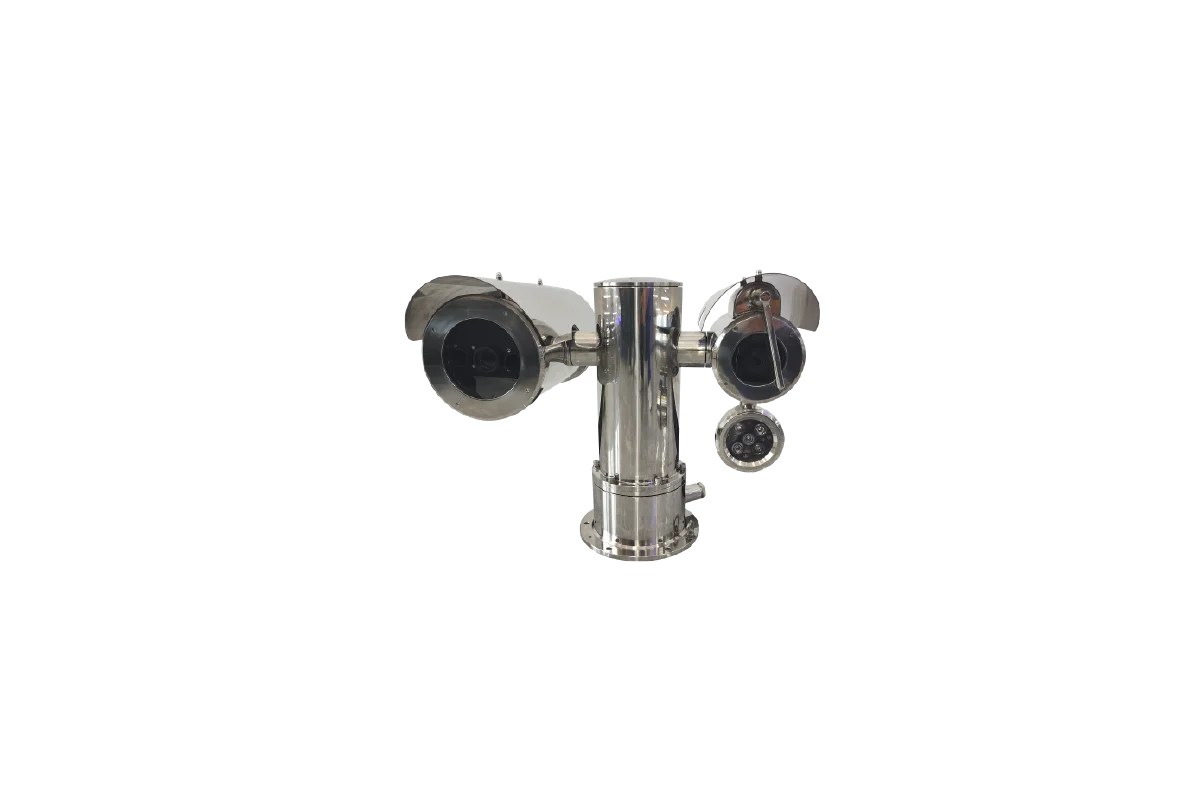

视频监控

摄像头安装于断路器室和电缆室。用于监视 接地刀和断路器的分合状态。具有数字宽动态、 3D数字降噪、背光补偿、 配合系统算法实现AI识 别、视觉感知等功能。

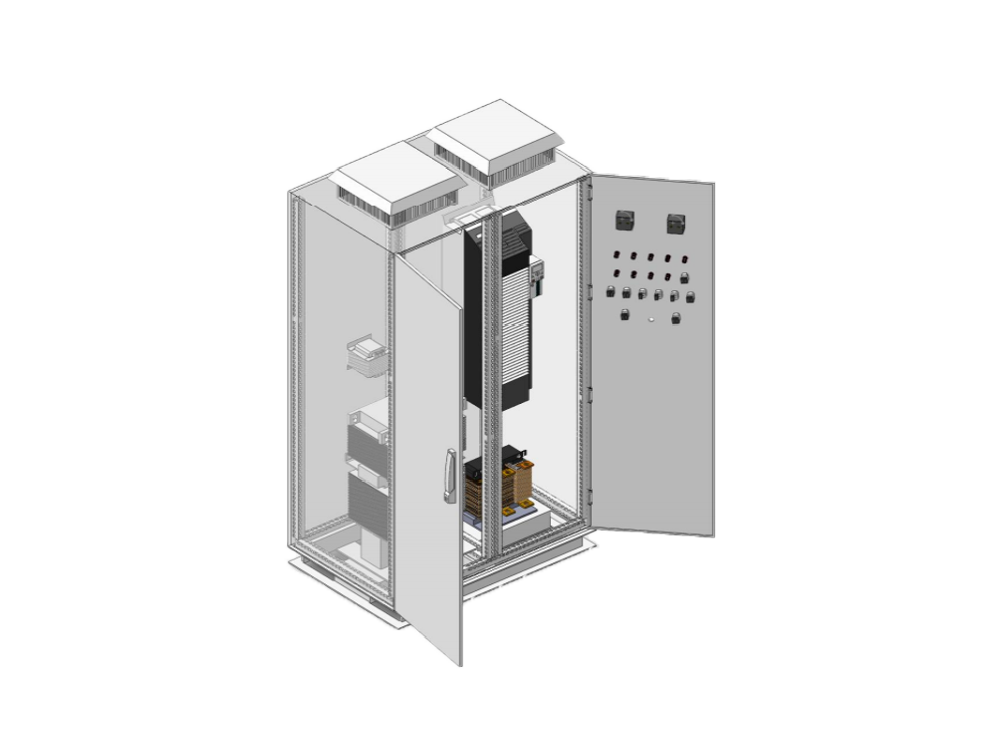

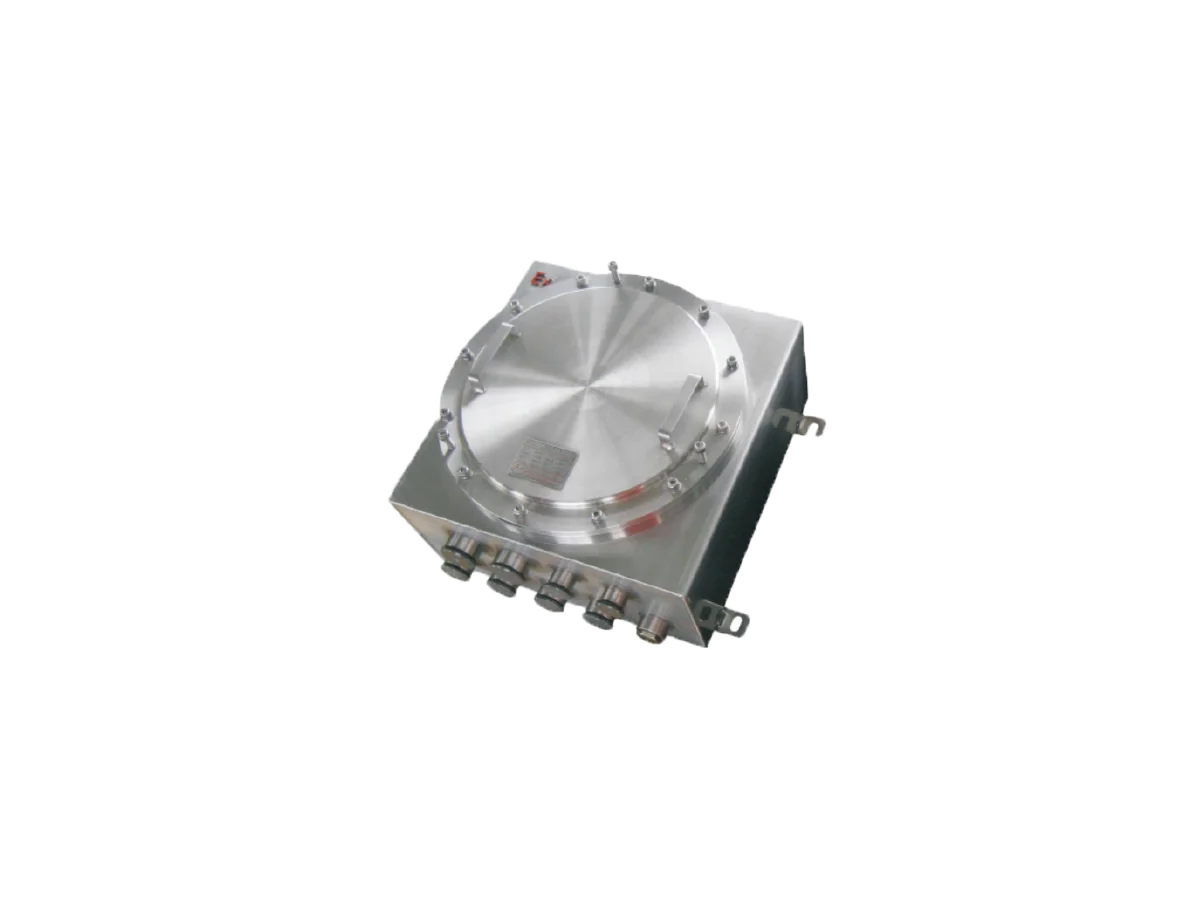

IED控制终端及人机交互

集成红外与可见光摄像头,支持视频分发 至SCADA及监测系统, 具备触点测温、 全电量 与电能质量监测、 机械特性测温功能, 支持多 路RS485和以太网通信接口, 并可采集信息上 传至人机交互终端及监测系统。

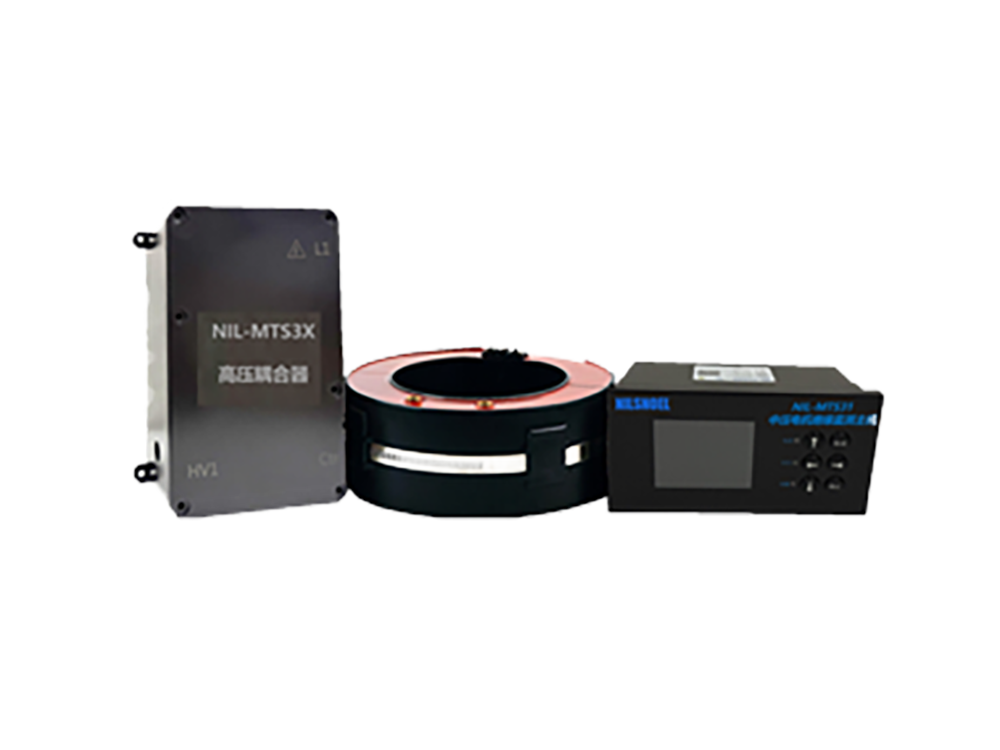

开关柜触头监测

集先进传感技术、数字识别技术、无线通信 技术、低功耗技术、抗干扰技术以及自动化控制 技术为一体的高新技术产品, 对开关柜触头进 行温度、夹紧力、 插入深度的实时在线监测, 系 统具有图像界面可视化、 阀值报警、 曲线分析、 查询统计、报表管理等功能。

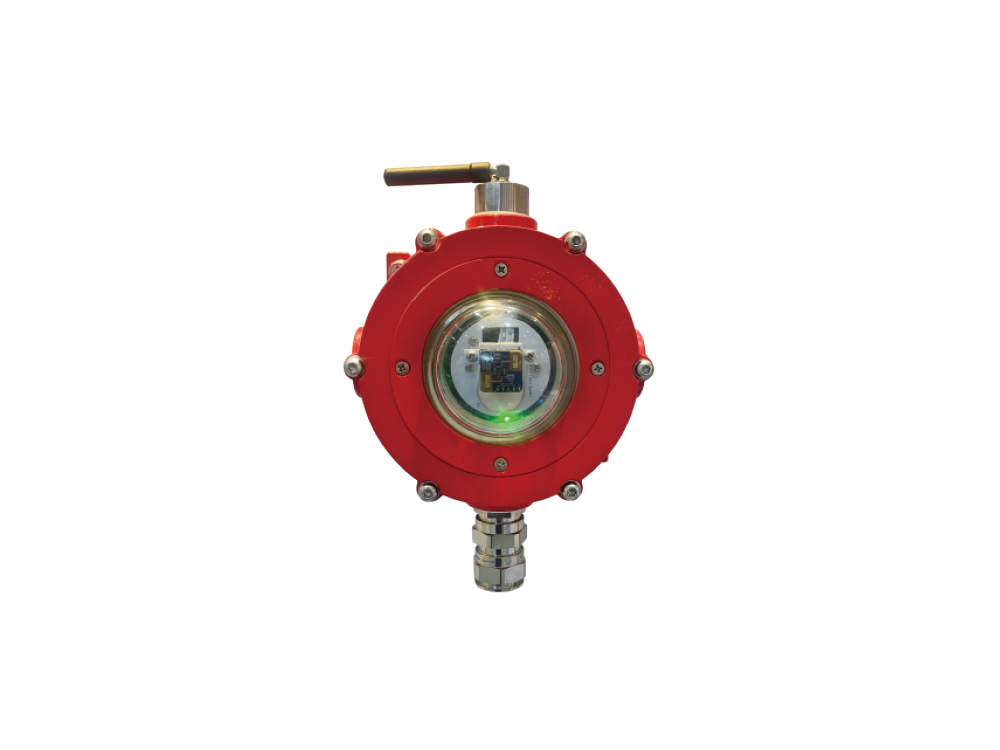

局部放电监测

实现对局部放电、温度、带电状态及故障状 态的实时在线监测与可视化状态指示, 为设备 运行维护提供全面的数据支撑。

机械特性及环境监测

实时采集断路器机械位移信号,精确计算刚 合、 刚分速度、 超程等关键参数, 并分析行程曲 线,确保机械动作特性符合标准; 实时采集柜内 温湿度, 通过温升监测有效诊断导电回路异常, 提前发现氧化、接触不良等隐患。

智能顺控逻辑

基于五防闭锁规则和预设操作流程,实现隔离开关的自动顺序控制,确保操作合规性。

多模态状态监测

集成局部放电、无线测温、机械特性、电气参数等多源数据,实现设备全维度健康评估。

AI 双确认机制

结合电气信号、机械状态及机器视觉三重校验,保障一键顺控操作可靠性。

自适应驱动保护

控制器具备堵转检测与智能退闸功能,防止机构卡滞或电机过载损坏。

在线客服

在线客服