变频控制柜解决方案

变频控制柜解决方案

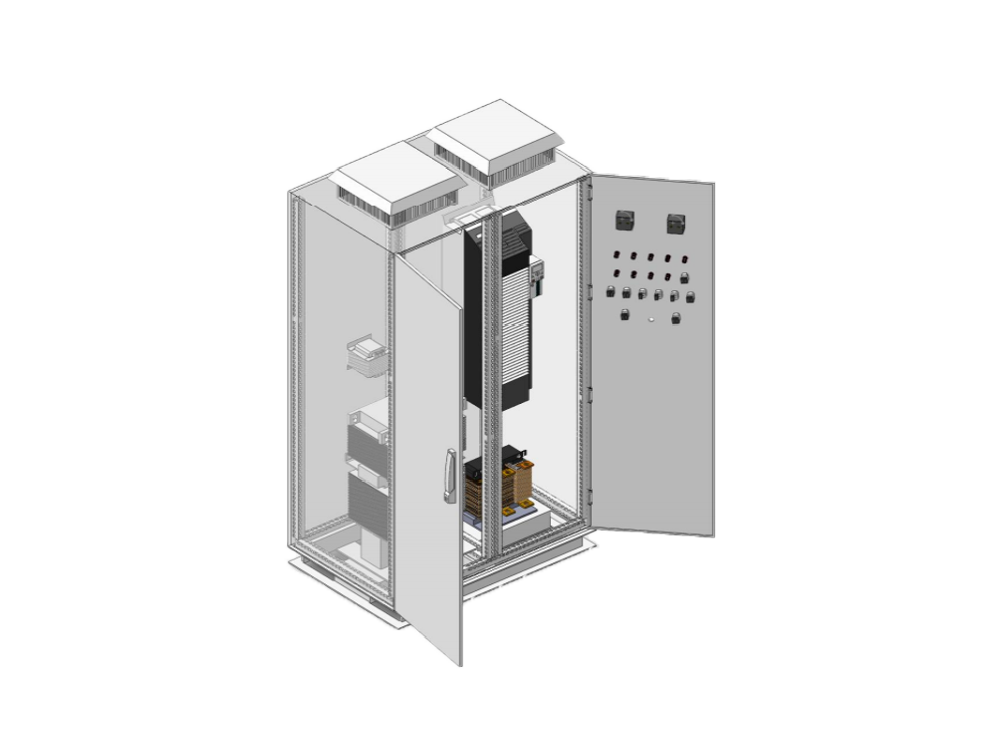

变频控制柜是专为复杂工业环境设计的综合性电气控制设备。它以高性能变频驱动器 (VFD) 为中心,集成了断路器、滤波器、散热器、PLC 和触摸屏等关键部件。其核心原理是调节电机电源的频率和电压,从而实现交流电机的平稳启动、精确的速度控制和智能保护。广泛适用于风机、泵、压缩机等设备的调速。

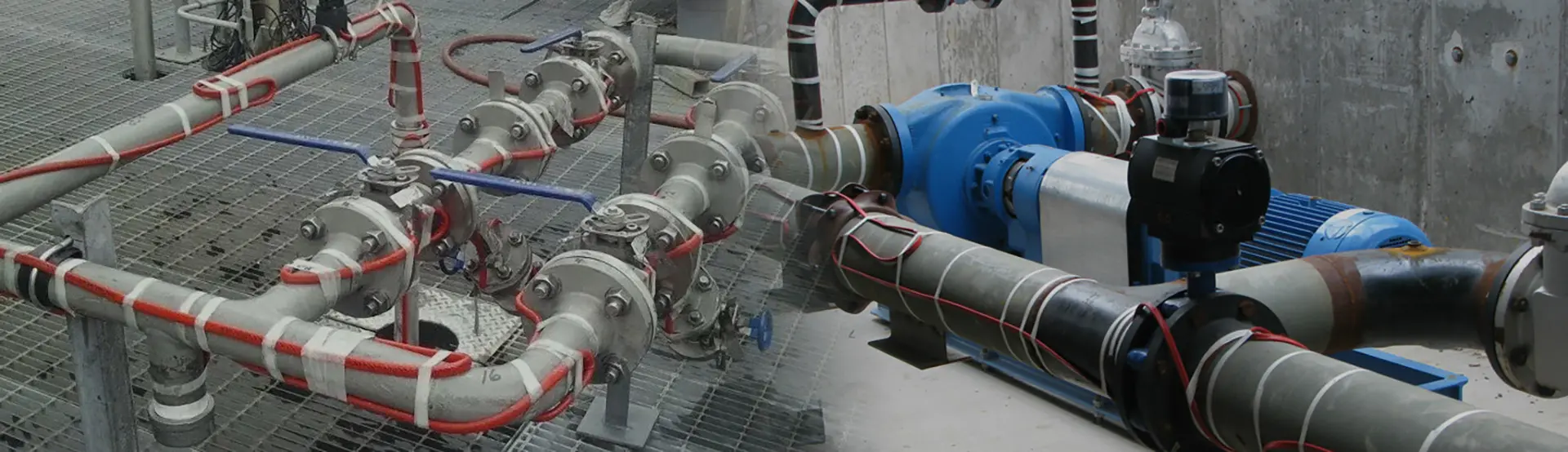

应用场景

————————

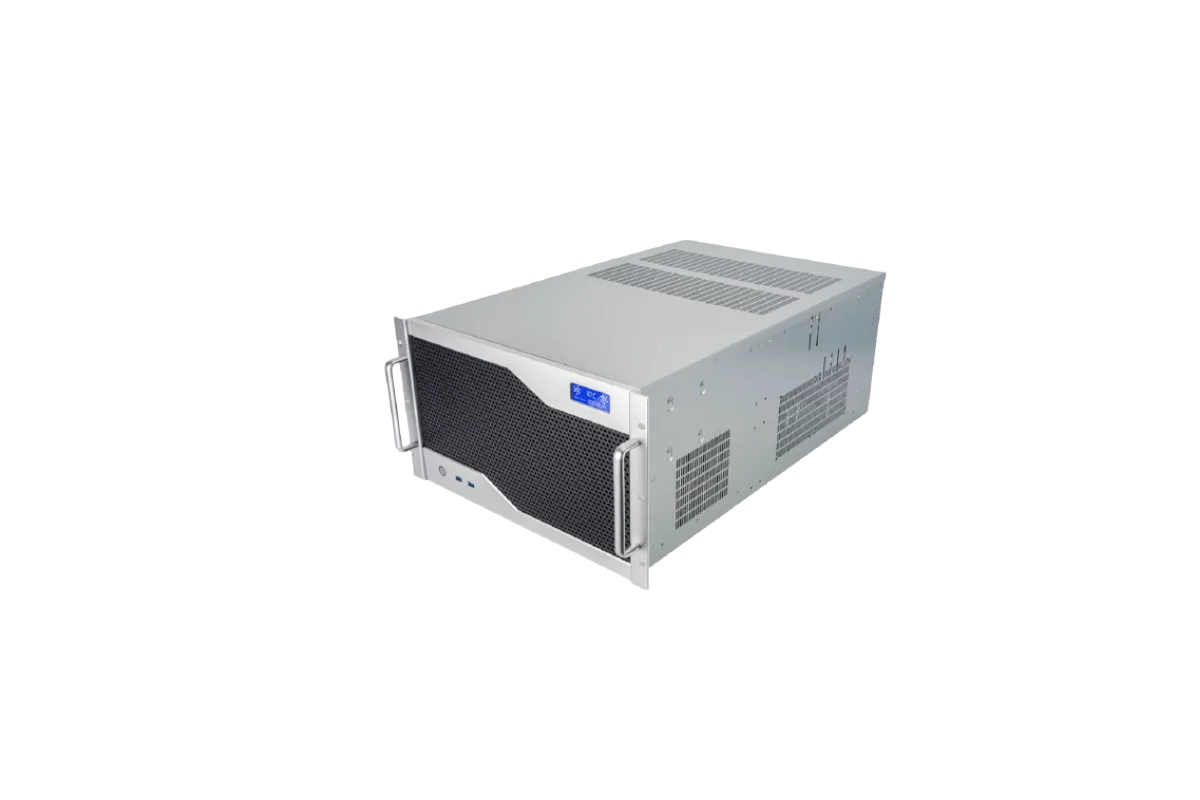

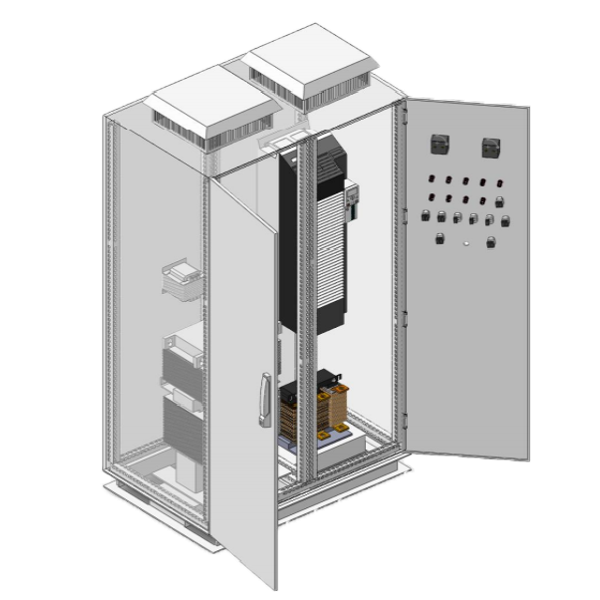

集成了变频器、 断路器、 滤 波器等电气元件,可自动调 节频率精准控制电机转速, 为风机、 水泵、 压缩机等设 备提供适配的动力,从而实 现高效节能、稳定运行。

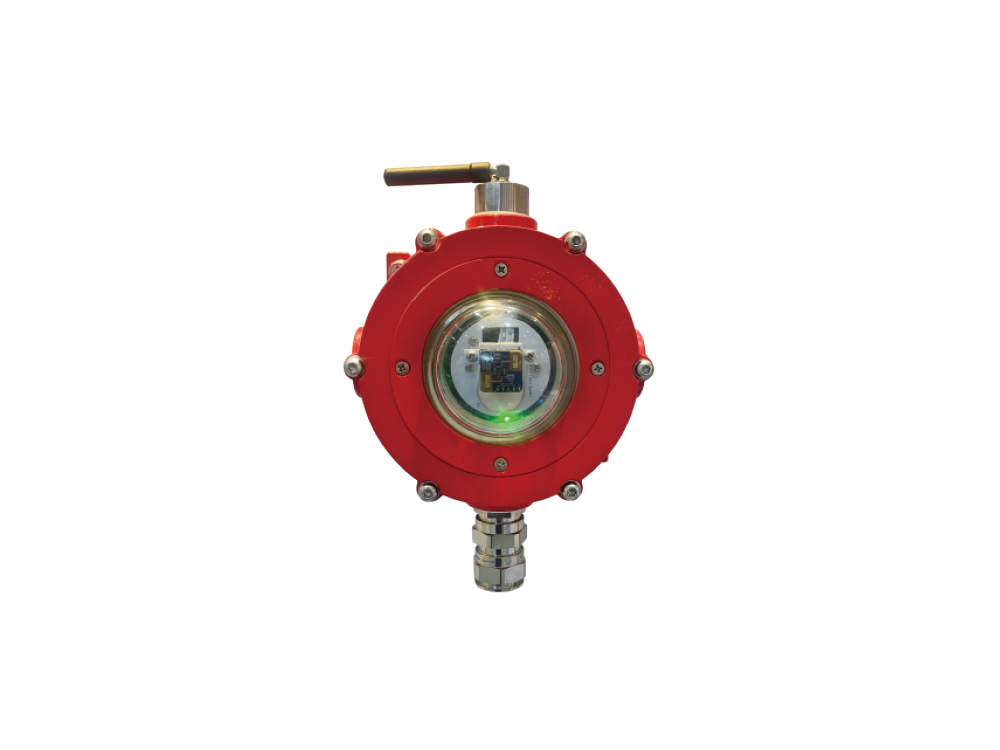

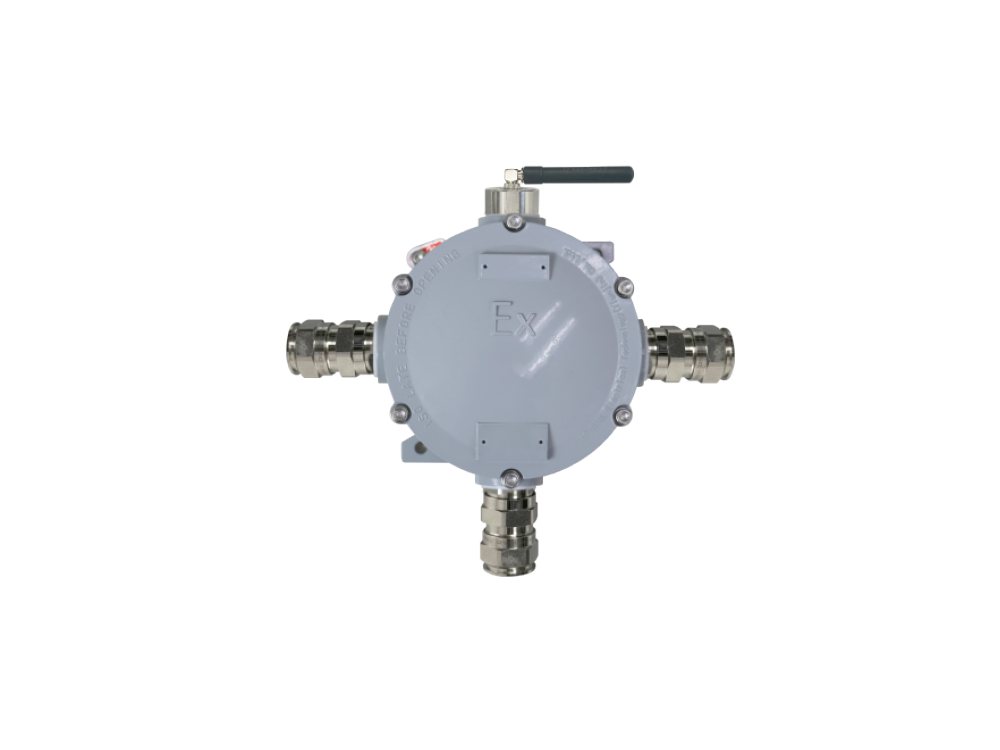

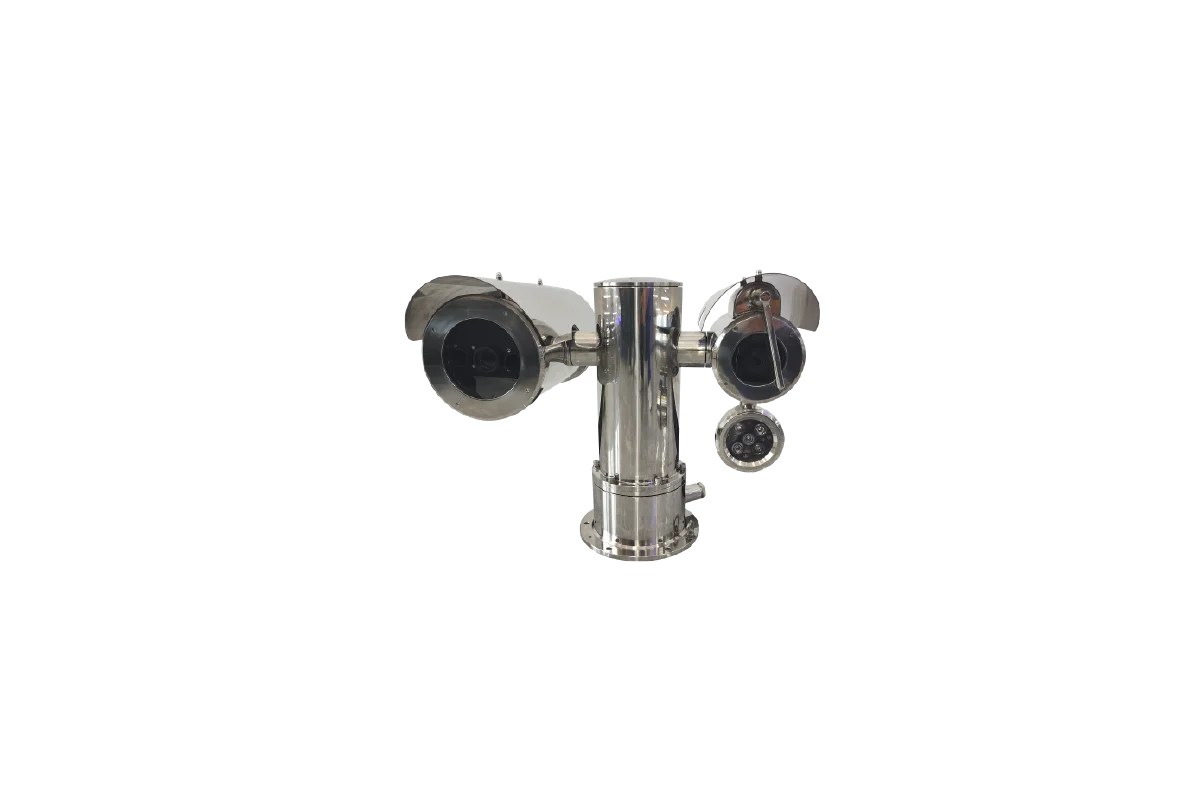

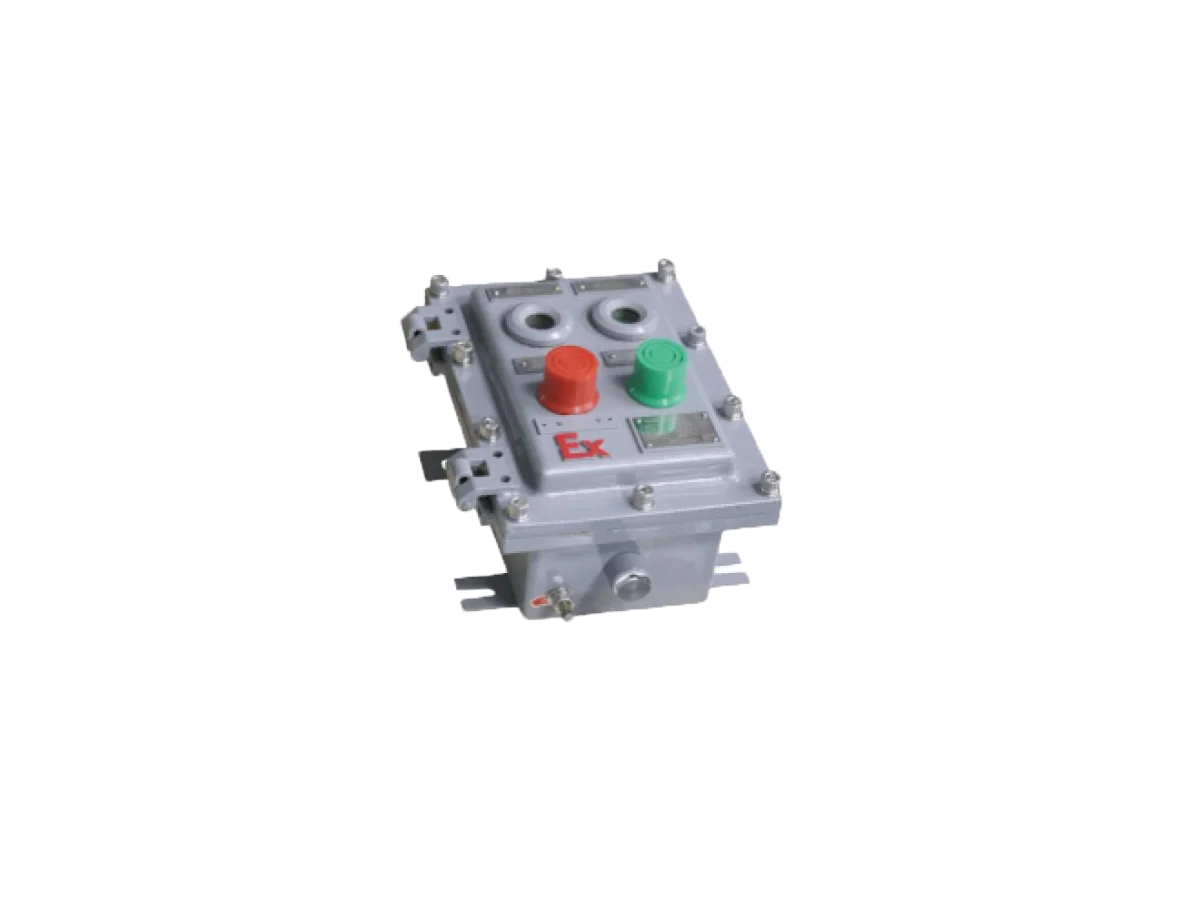

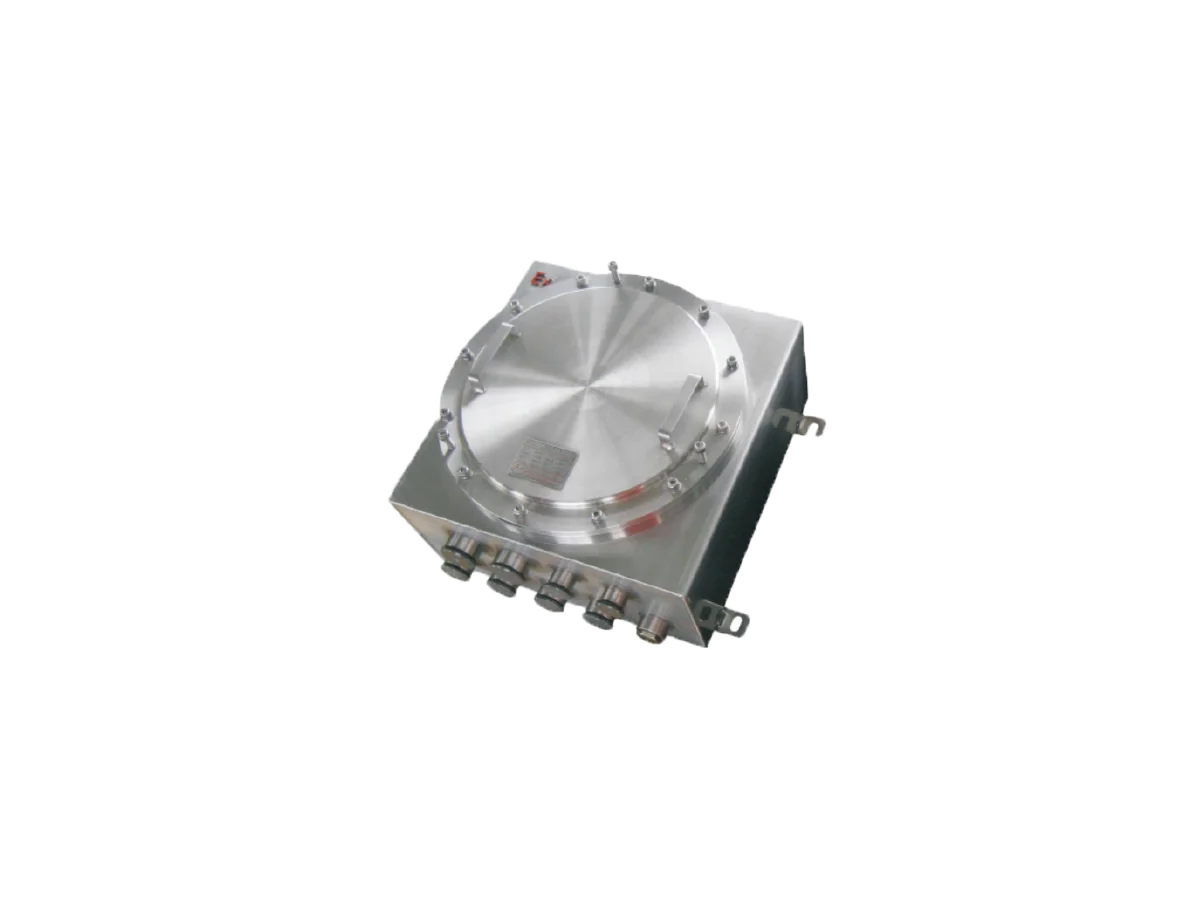

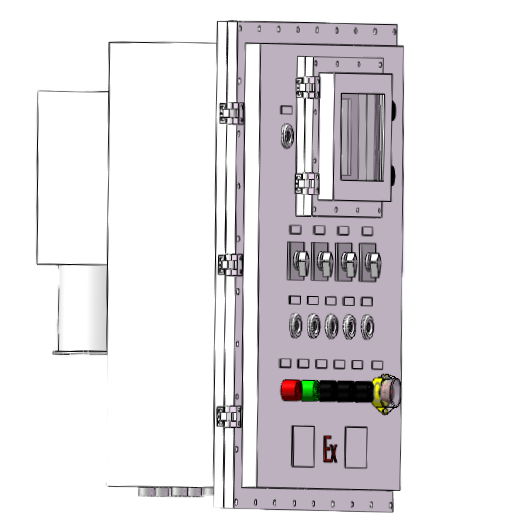

能在易燃易爆环境(如化工、油气区)中,通 过特殊防爆结构与元件设计阻断内部火花/ 高温引燃外部危险气体, 同时实现变频调 速功能。

室内变频器机柜

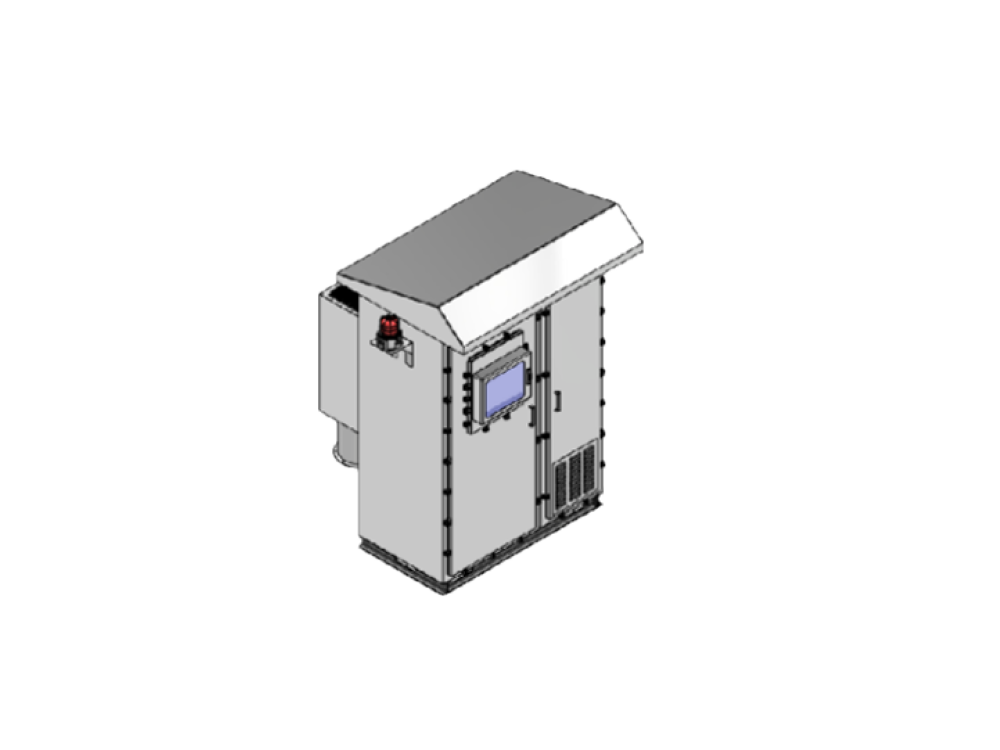

防爆变频柜

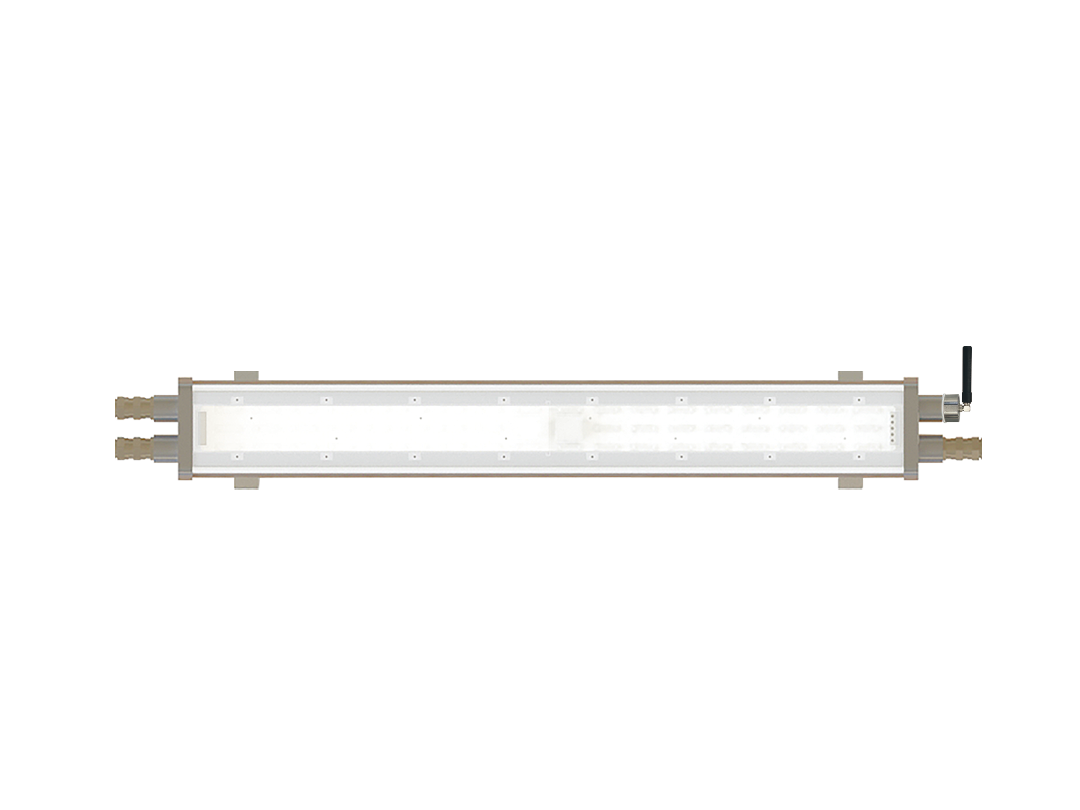

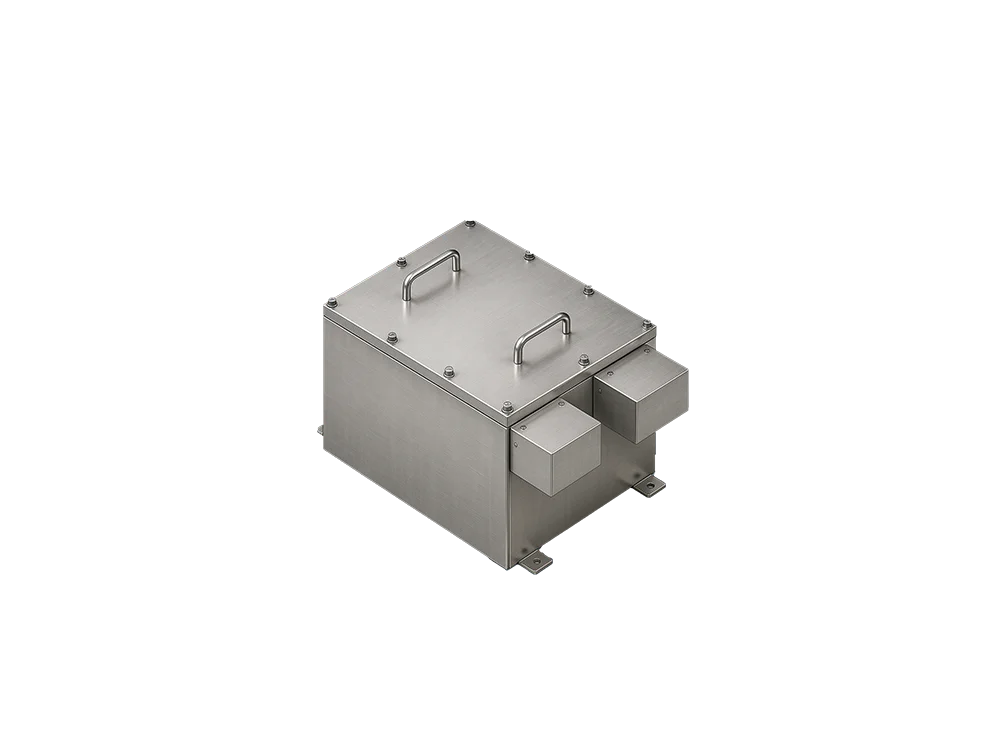

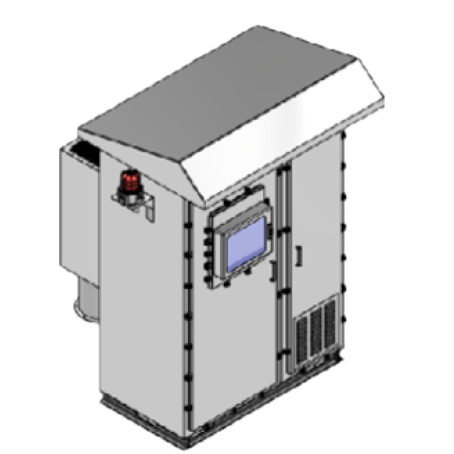

室外变频柜

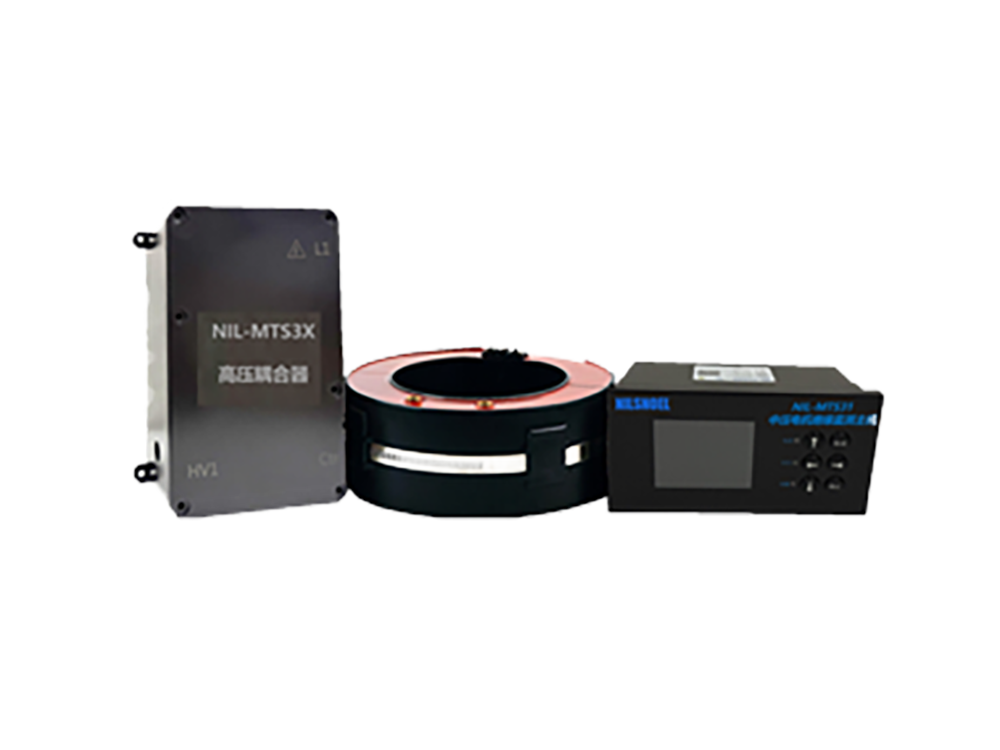

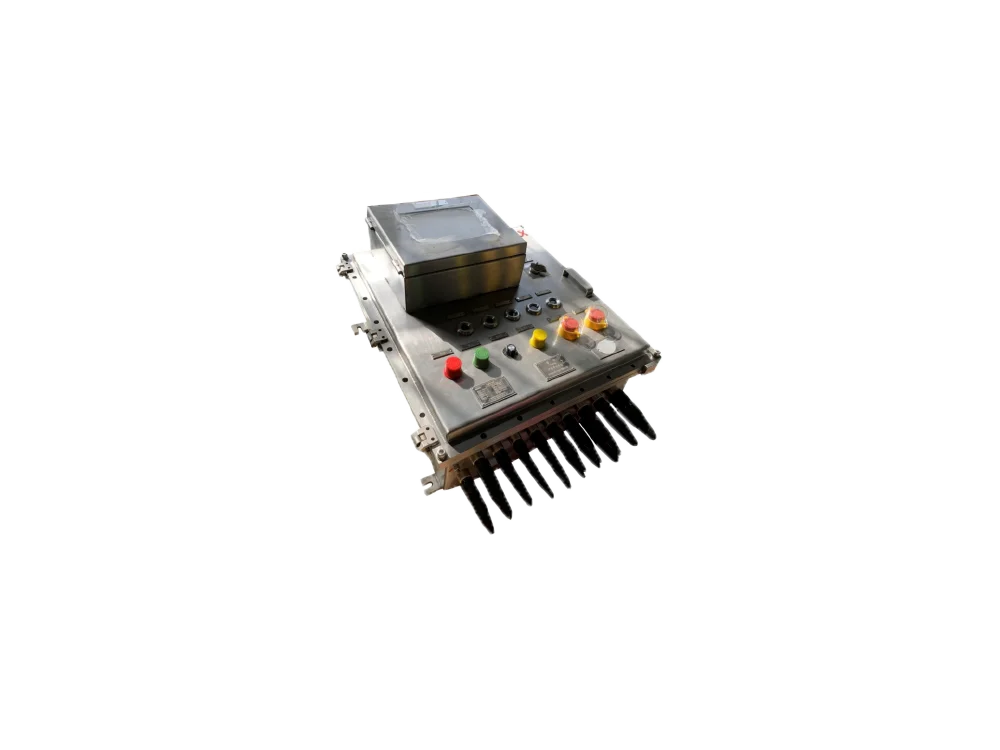

高压变频柜

采用高防护等级密封外壳,预留足够散 热空间,适配户外复杂环境,如高温、高湿、盐雾、风雨等,通过变频技术调节高 压电机转速,实现变频调速功能。

用于高压供电场景(通常电压等级≥3kV), 通过变频技术调节高压电机转速,实现高 压设备节能运行、精准调速。

高可靠性:在恶劣环境下性能稳定

核心变频器由国际知名品牌定制,内置四重保护功能(过流、过压、欠压、过载)。它确保在高温、灰尘和振动等苛刻的工业环境中长期稳定运行,显着降低计划外停机的风险。

节能增效:降本与性能提升双重驱动

配备先进的高精度控制技术,优化运行条件,同时动态匹配电机负载要求并调整效率,以最大限度地提高功率利用率。跨多个行业验证,有效降低运营成本,帮助企业实现绿色低碳生产。

高智能:实现预测性维护

集成PLC和触摸屏,支持两大核心功能:(1)可定制系统和保护参数,实时故障报警,快速排除故障;(2)自动存储和查询历史运行数据,为设备健康分析和预测性维护提供有力支持,减少意外故障。

定制性强:适应多种场景

凭借灵活的系统集成能力,它可以与客户现有的自动化系统无缝对接。它还根据不同行业和设备应用需求,提供从参数配置到结构设计的一站式定制解决方案,避免“一刀切”的问题。

易维护性: 提升管理效率

采用模块化设计,组件分工明确、拆装便捷;同时支持通过网络实现远程监控与维护, 减少现场巡检工作量,便于快速排查故障、响应设备问题,显著提升管理效率与运维 响应速度。

在线客服

在线客服